The Chip Breaker

It might seem hard to believe, but the modern hand tool woodworking world only really began to accept the value of a close set chip breaker about 10 years ago. A video from a group of Japanese researchers in the 80s was re-discovered, analyzed, and as more woodworkers experimented as a result, its benefit became fairly settled.

The chip breaker, also known as a cap iron, was introduced to hand planes some time between 1750 and 1770. At the time this was called a “double-iron” plane.

Its purpose is to combat tear out. On a plane for rough work the breaker can be set far back from the edge of iron quite happily. But for a smoother the closer to the edge of the iron the better when it comes to combatting tear-out.

The main purpose of a chip breaker for beginners, unfortunately, is to cause their hand plane to clog.

If you want to see the video that pretty much settled the debate on the value of chip breakers, see here:

https://giantcypress.net/post/23159548132/this-is-the-full-version-of-the-video-created-by?8de140f8

before you go creating new bevels on your cap irons, most planes cap irons are near optimal already, particularly the modern ones. If it mates well and is polished, you are good to go. If you are getting clogging and the shavings have an accordion texture, you need to smooth and polish your chip breaker a bit more

David Weaver wrote a fantastic article on the mechanics with practical tips for preparation

https://www.woodcentral.com/articles/test/articles_935.shtml

Before you go crazy on all of your planes, there is no need to keep it close when not smoothing, and it may make it harder to plane. A jack plane for rough stock removal is not going to benefit much.

The bend in the Stanley cap iron was a (patented in 1867 by Leonard Bailey) innovation to allow a chip breaker to be used with a thin iron. By ensuring pressure only at the tip of the iron where it was counter acted by the pressure from planing, buckling was reduced. It also plays a role in preventing chatter in a plane with a thinner iron. Thicker irons like those in wooden planes, and newer high end planes like a Lie-Nielsen, don’t need the hump to be effective.

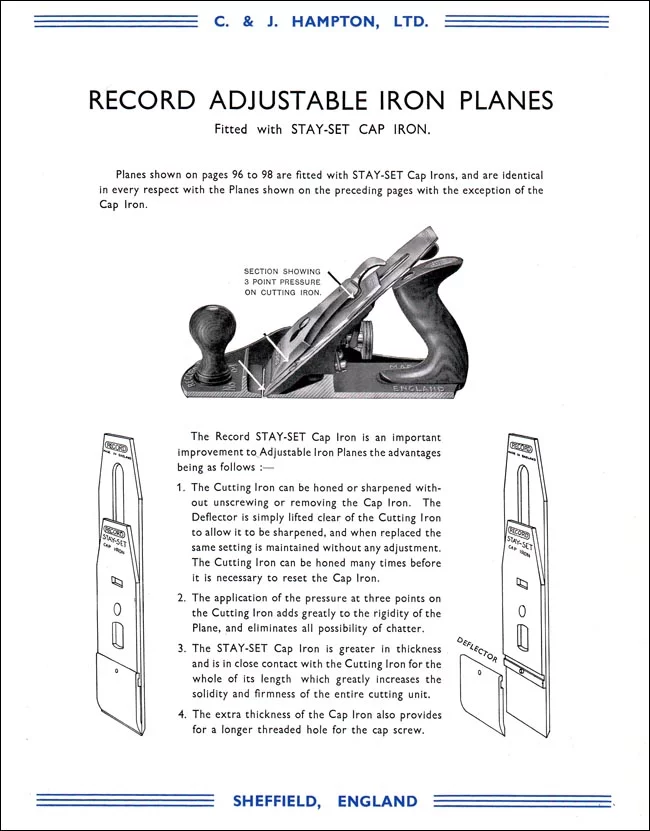

While knowledge of how to set up a chip breaker for smoothing became consensus relatively recently, its more re-discovered than discovered. Planecraft (published by C J Hampton of Record fame) gave the following advice in 1933.

Set back 1/64th for smoothing work 1/32 to 1/16th for rough work for hard woods with irregular grain - as close as you can get.

Record also introduced the Stay-set chip breaker (Still used by Clifton), where the breaker was in two parts, with the part nearest the cutting edge removable to, in theory allow sharpening without losing the breaker setting. How much benefit this really provides is debatable. Many of the stay-set breakers are subject to slop. Chris Schwarz explains David Charlesworths method for removing slop from a stay-set chip breaker here:

https://www.popularwoodworking.com/woodworking-blogs/tightening-stay-set-chipbreaker/

If your chip breaker will not mate with the iron, I recommend following the steps in James Wright’s video here:

https://www.youtube.com/watch?v=cQzLdMsGCqk

I’ve been known to be fairly brutal in my repair techniques at times, hitting them with a mallet and bending in a vice if necessary.

Finally, a close set chip-breaker is not the only, or even a necessary way to combat tear out, just one tool for doing so. Many fine plane makers make excellent smoothing planes without chip breakers.

Some useful links:

wonderful history and very practical advice on preparing a cap iron

https://smallworkshop.co.uk/2016/02/14/bench-planes-the-cap-iron/

Great comparison of different chip breakers

https://www.inthewoodshop.com/ToolReviews/LVChipbreaker.html

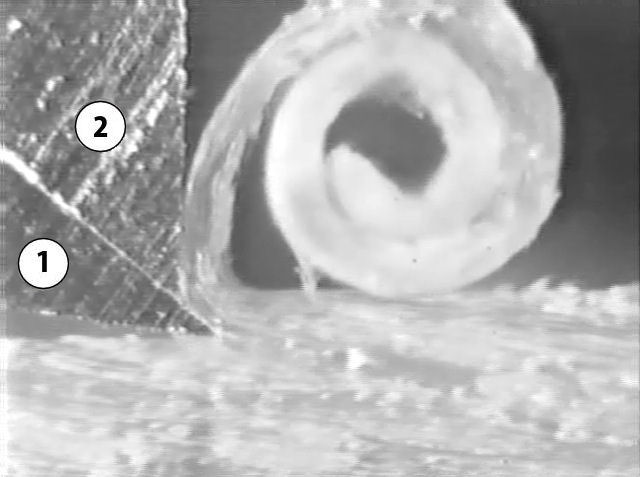

The action of a chipbreaker as seen with a microscope

Samuel Carruthers advertises double irons in the Pennsylvania Chronicle 1767

A well set chip breaker, I have gone closer on occasion

A Clifton stay set chip breaker

A clogged chip breaker, if you have this problem your chip breaker and iron are not mated correctly.

Laddered shavings, if you have this problem your chip breaker needs more polishing near the chip, the shavings are catching on it.

A modern Lie Nielsen chip breaker in the foreground, a classic stanley chip breaker in the background.

A Record Stay-Set two part chip breaker.

The Record Stay-Set as advertised in their catalogue.

A properly set chip breaker, not the small undercut at the tip