The Card Scraper

The humble Card Scraper (also called a Cabinet Scraper) is as simple a tool as can be found. A flat piece of steel capable of conquering the trickiest pieces of wood , that even the fanciest planes will struggle with.

Scrapers are among the oldest of tools. Flint scrapers for preparing hides are almost as old as humans. While steel scrapers are popular today. Glass scrapers where also traditionally used (see a demonstration here https://www.youtube.com/watch?v=MBLdVKmcPw8a)

When prepared and sharpened correctly the scraper cuts with a small burr on its edge. How to create that burr is a matter of much controversy, any two users of the tool will always seem to have a slightly different method. When I first started using these tools, I rarely managed to produce anything but dust.

A few suggestions

-

Get a good burnisher, some woodworkers say a smooth screwdriver, back of a chisel or something else will do the job. I think they are probably using scrapers made from old saw plate or vintage scrapers. If you buy a new scraper today its probably significantly harder than a vintage scraper. Vintage scrapers had a rockwell hardness of around 40, modern ones around 50. I like the Arno burnisher. I also used the Veritas variable burnisher jig for quite a while. Its good, and its a quick way to burnish reliably, I find I can now get a better result with the Arno.

-

Thick scrapers are easier to polish than thin scrapers. I recommend going at least a little thick when starting out. There are other pros/cons though. Scrapers get hot during use, hot enough to be uncomfortable to hold. A thin scraper gets hotter faster than thick. However a thin scraper takes far left effort to bend and is easier on the thumbs. Some people attach a magnet to their scraper in use to act as a heat-sink, or tape their thumbs.

-

Some say scrapers are only good for hard wood. I’ve scraped pine, its more difficult to get the angle right, and you need to do a good job preparing the scraper. but you can definitely do it.

-

Try to avoid sanding before scraping. Small particles of left over abrasive will dull your scraper quickly.

So how should you prepare your scraper?

As a major fan of the “The Schwarz” I recommend reading this article

https://www.popularwoodworking.com/techniques/a_better_way_to_sharpen_scrapers/

If you follow it, you have a good chance of getting a working scraper. I particularly like his adaption of the Charlesworth ruler trick to card scrapers.

Schwarz expanded on this in a very long very detailed lecture here:

Chris Schwarz - Scrapers History, Preparation and Use

https://www.youtube.com/watch?v=TF4iQrafwbc - Part 1

https://www.youtube.com/watch?v=c8txCjpXj4I - Part 2

https://www.youtube.com/watch?v=FoXHlJU6O9A - Part 3

For a more recent and shorter video, I quite like Matt Estlea’s guide (worth watching for his demonstration at the end alone)

https://www.youtube.com/watch?v=mfgCQ4lyBrQ

Finally, just for fun, watch this video and try making your own!

Wood by wright - How to Make a Card Scraper From an Old Hand Saw

https://www.youtube.com/watch?v=mfgCQ4lyBrQ

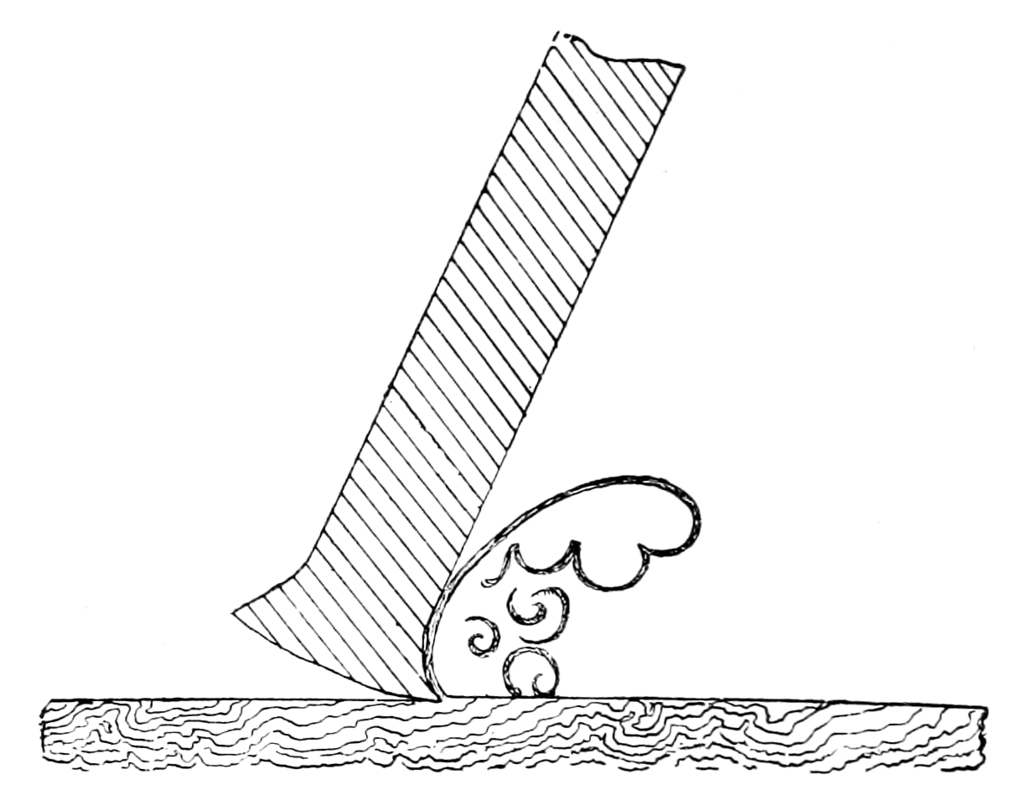

An illustration of the cutting action of a scraper. The burr is in near constant contact with the surface its cutting, and can only make a realatively shallow cut. This limits its ability to lift the wood fibres ahead of the cut, which is what causes tearout, although the constant contact can generate a lot of heat, making it difficult to work the scraper with bare heands for long periods.

A well prepared card scraper in action.

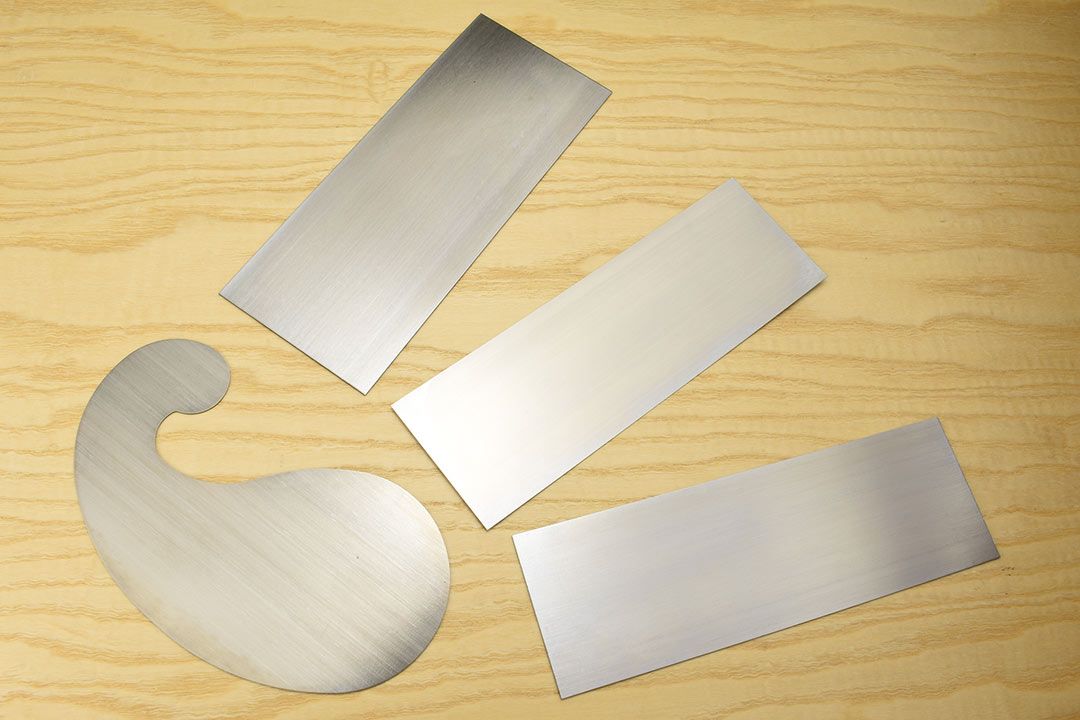

Card scrapers are available in a variety of shapes and sizes.

The Arno burnisher is my personal favorite for preparing card scrapers

The Cruible Tool card scraper’s shape was taken from one favored by chair maker Chris Williams, its also comes with a magnet to use as a heat sink