The Stanley 46

The Stanley 46

The Stanley 46 is the lesser known cousin of the Stanley 45 & 55. Like the other Stanley combination planes it can rabbet, dado, plough grooves and be used as a tongue and groove plane. It has far fewer cutters than the other Stanley combination planes (11 cutters, vs the 22 of a 45, or 55 of a 55). But it is a skew mouth plane, making it far more suitable for cross grain work, or even working against the grain.

The cutters for the 46 are not only skewed at the tip, but also along the sides,as a result, cutters for the 45/55 will not work in the 46 and making replacements is tricky. Its easy to find a 46 with only a single cutter, but the price and rarity of replacement cutters makes buying a user lacking cutters can often be a false economy.

The standard set of cutters includes a Tonguing tool, 3/16”, 1/4”, 5/16”, 3/8”, 7/16”, 1/2”, 5/8”, 7/8” and 1 1/4” as well as spurs and a slitting cutter.

The Saint James Bay Tool Company occasionally produces runs of replacement cutters.

http://www.stjamesbaytoolco.com/

The 46 has 3 main parts, the body, a sliding section and the fence. The sliding section is used to provide support for the wider cutters. Both the sliding section and the body have nickers with the bevels facing each other, again making it excellent for cross grain work.

Early models had a detachable guard plate which is often missing. If you see holes in the sliding section with no plate, your plane is missing a part.

The 46 was produced from 1873 to 1942. For a user, I recommend a type 10 or later (1905+). It has a rosewood fence that gives a larger registration surface, and gives you to option to make your own larger fence if desired. On an older 46 you would have to drill holes in the fence to do the same, and if you are the kind of savage who would do that to an early 46, I’m not sure we can be friends.

If you are curious how this works in practice here is a nice video of a 46 in action

https://www.youtube.com/watch?v=jZkqHdqe3fU

I could not possibly give a better guide to using a 46 than the steps laid out in Derek Cohens wonderful comparison of a 46, a Veritas Combination Plane and a HNT Gordon Dado plane at

https://www.inthewoodshop.com/ToolReviews/VeritasCombinationPlane-dados.html

In short, if you stumble accross a 46 in decent shape with a full set of cutters and you have cross grain work in mind, its worth snapping it up!

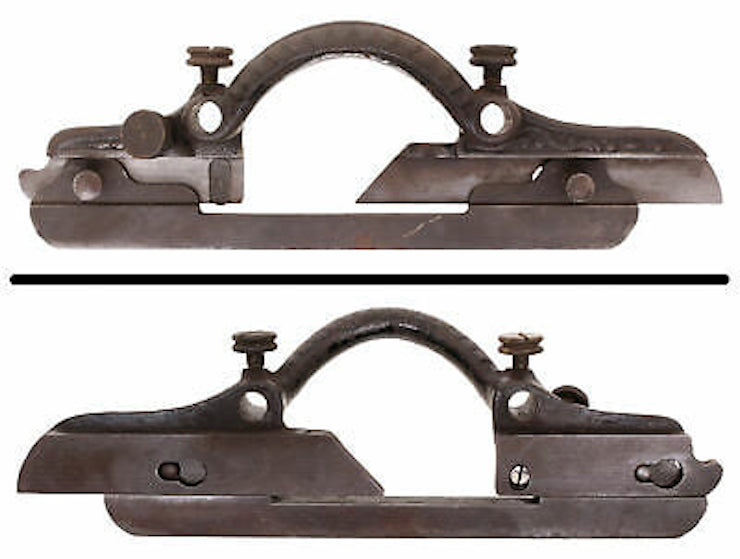

My two 46’s and a full set of cutters they have to share. The 46 on the right is a later model and my preferred user due to the rosewood fence.

**

**

A closeup , note the nicker on the sliding section. There is a matching nicker on the body, allowing both sides of a dado to be slit ahead of the cutter if the sliding section is aligned correctly. The bevel of the nicker should be facing outwards on both sides.

**

**

Here you can see the other nicker on the opposite side of the plane, along with the slitting cutter fitted to the plane on the left, and both have their depth stops in place.

**

**

A view from below. You can clearly see the skew of the blade, and how the sliding section supports a wider cutter.

**

**

An early model sliding section with the guard plate. If you have holes in the section, but no plate, you are missing a part.

**

**

A St. James Bay set of replacement cutters.

**

**

The early 46 was japaned, not nickel plated. The nickel plating on just about every 46 I have ever come across is quite thin and worn. If you see a pinkish hue, that means its worn so thin a little of the copper layer under the nickel plating is showing through.

**

**

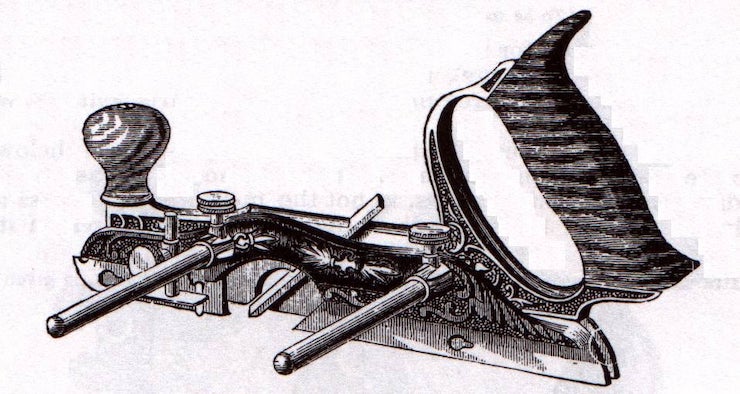

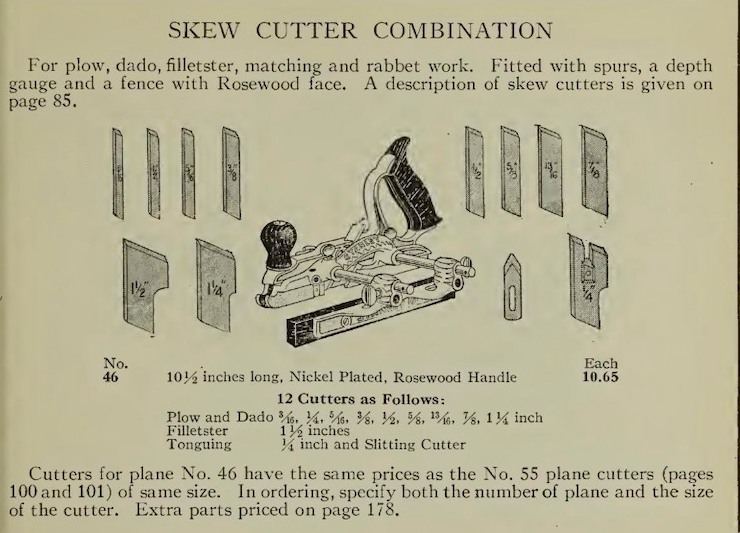

As shown in an 1882 catalog

**

**

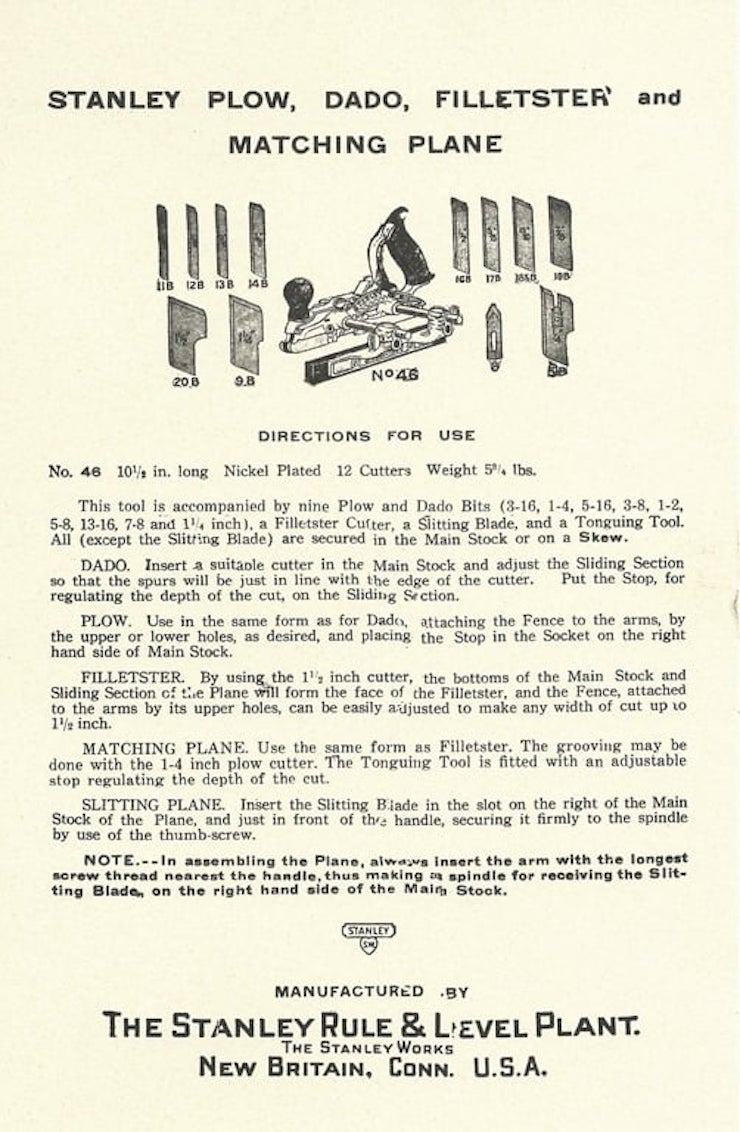

From Stanley catalog no 34, 1929

***

***