Gouges - Innie or Outie?

I love curved work. Most projects I undertake involve some curves somewhere, leading to my love of turning saws, spokeshaves etc. But few woodworkers I meet use a lot of gouges, they seem to be largely relegated to carving.

Gouges are to curved work what chisels are to the square. A good sharp gouge can achieve things that would be slow painstaking operations any other way.

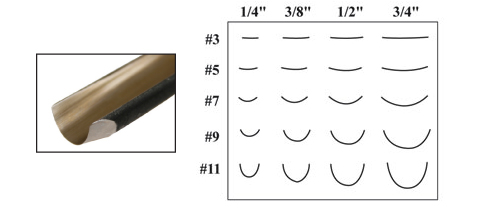

Gouges come in two main forms. The most common is the outcannel gouge, with the bevel on the outside of the curve. These are very familiar to carvers. You hold the tool up at an angle, riding the bevel to make a cut. The curve of a gouge is known as the “sweep”, There are no number 0 gouges, that would be a chisel, a 6 to 8 is a good starting point. A gouge with a big sweep is a great tool for roughing out material quickly. Think of it as the scrub plane of the gouge world.

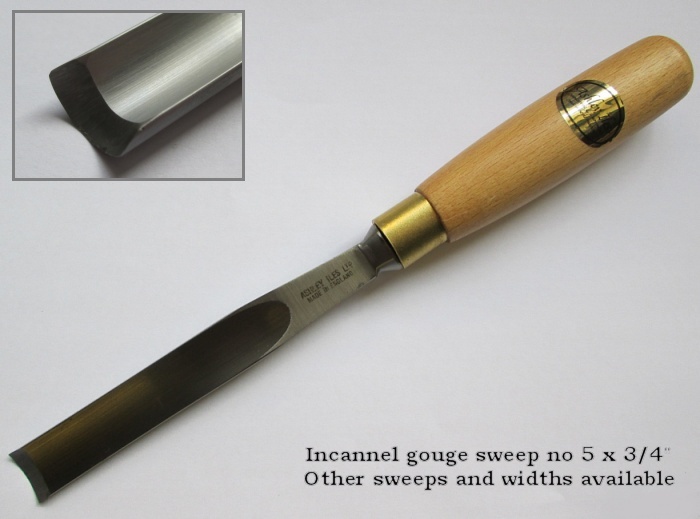

The other main form is the incannel gouge. As the bevel is on the inside of the curve, these are chiefly used for forming curved channels. As with a pairing chisel, the back of the gouge is your reference surface, allowing you to pair a long straight channel through your work. If you are struggling to think of why you would want such a tool, check out this video by Bob Rozaieski https://www.youtube.com/watch?v=FZT5vWaJUvw . He demonstrates cutting the same shape with and without the gouge, if you like curved work, its a pretty convincing demonstration and why you should add an out cannel gouge to your tool kit.

Selecting vintage gouges to buy is very similar to selecting chisels. With an in cannel gouge you still want a “flat” back. Its going to be a reference surface so you don’t want pitting there, just like you would not on a chisel.

Sharpening gouges is going to be a free hand operation, there are no jigs I know of that eliminate the need to be able to free hand. Your normal stones will suffice for an out cannel gouge, buy you are going to want some sort of slip stone, or a dowel and some sandpaper to properly deal with an incannel gouge. If you are planning on griding an in-cannel gouge, a narrow grinding wheel is near essential, look out for a 1/4 inch wheel.

In cannel gouges are often referred to as pattern makers gouges, but they were far from exclusive to the pattern making trade. A very useful variant that was common in the pattern making trade is the cranked incannel gouge. If you need to make a long channel, sooner or later your handle is going to reach the work piece, at which point you will no longer be able to use the back of the gouge as a reference surface. The cranked gouge offsets the handle above the blade allowing you to continue without the handle upsetting your cut.

Another variant I have yet to try myself is the bent gouge. The entire blade is curved allow it to follow curves into steep hollows.

Finally, don’t forget, the Blunt Chisel technique works with gouges too!

Some great videos:

Bob Rozaieski’s videos on restoring an in cannel gouge

https://brfinewoodworking.com/restoring-an-in-cannel-gouge-part-1/

https://brfinewoodworking.com/restoring-an-in-cannel-gouge-pahrt-2/

Mary May, the Queen of Carvers on sharpening a gouge

https://www.youtube.com/watch?v=i5iEhUoSi8Q

The Paul sellers Approach

https://www.youtube.com/watch?v=m-Dy7R8xQBM

The Renaissance Woodworker on “Pattern Makers” gouges.

https://www.youtube.com/watch?v=DRhih_MALHQ

Mary May - all about gouges

https://www.youtube.com/watch?v=ukKFqepstgU

Mary may on tool sweeps

https://www.youtube.com/watch?v=0REAVEaK-zE&

3 Gouges that every Guitar Builder needs in their Workshop Crimson Guitars

https://www.youtube.com/watch?v=LRHmB-FdTKg

This and other diversions are archived at https://blog.vintagetoolpatch.com, ifyou would like to write one, let me know!

A typical out-cannel gouge being used for carving. The tool is raised up at an angle, and the user rides the bevel to control the depth of cut.

The bevel on an out-cannel gouge.

An in-cannel gouge, with the bevel on the inside of the gouge, and a curved channel chopped with the tool. As the back of the in-cannel gouge provides a reference surface, its far easier to make a shape like this even than with an out-cannel gouge.

A selection of gouges with different sweeps. On the far left, a v tool, then 3 gouges with increasing sweeps.

A diagram illustrating different sweeps at different tool widths. Some combinations of sweep/width wind up being equivalent. Vintage gouges often have no sweep marked on them, sweeps appears to have been somewhat standardized in the 1950s.

A modern alternative to the slip stone are diamond cones.

DMT also sell the “Diamond Wave”, find a spot on the wave that is a close match to the sweep of your tool and work back and forth like a sharpening stone.

The bent gouge. Allows the user to follow steep inner curves.

Grinding an in-cannel gouge. The stop block is used to allow you to roll the tool on the grinding stone to follow the bevel. Note the very narrow grinding stone being used.

Cranked gouges. The offset handle allows the user to follow a channel past the point where the handle would normally interfere with the cut.