Cross Water Cottage Tools

I truly believe we are now living in a new golden age of hand tools. We can buy off the shelf tools, and probably have them delivered to our door, that arrive ready to use, and manufactured with a degree of precision that outshines all but a handful of manufacturers from the days when hand tools ruled the world.

What truly has convinced me that this is the best of all times to be hand tool woodworker are the pieces by the small makers. They turn out unique pieces that are as close to art work as they are functional tool. I’ve slowly been adding pieces to my collection and almost every one has become a regular user. These tools tend not to be budget options. A lovingly made one of a kind tool does not sell for the same price as a mass manufactured one. But in my experience they are worth every penny. The makers of these tools seem to delight in conversation with their users. In some cases I’ve received regular updates on the process of making the tool as it passes from stage to stage. Advice on their use. And these makers delight in seeing the finished pieces their users create.

With this in mind, I’m going to start using these tool diversions from time to time to profile modern small tool makers. If you are one, and would like to be profiled here, please reach out and let me know.

First up is my most recent acquisition. A Cross Water Cottage Tools Chamfer plane. First a disclaimer, I’ve known Chris Byrne on Facebook for a long time, he is a fellow Irish tool lover, so I’m perhaps not the most impartial reviewer in the world. That said, I love this plane. Chris has been an antique restorer, a creator of intricate miniatures and now has turned his hand to plane making bring decades of experience to his pieces.

This plane is a sliding box style Chamfer plane. Chris has taken an established form and very much made it his own. The “sliding box” portion acts as the sole of the plane as you cut the chamfer. The depth of the box & iron determine the size of the chamfer. Once the chamfer is the correct size, the side walls of the sole contact the work and prevent the iron from cutting any deeper.

Unlike any vintage sliding box planes I have seen, the wedge is inserted in front of the sliding box on this plane. While I have not used any vintage models, to my eye, this would appear to make adjusting the plane simpler, although setup is a little tricker. I find I need to assemble the wedge, iron and box outside of the plane and insert them as a unit, then tap the wedge to secure them. I set the iron just a little shy of projecting past the box when I do this, and then tap to have it project after all the pieces are in the body. This plane works best with a very shallow cut, so no more than a 16th of iron projection.

The sliding box design has advantages and disadvantages. The short sole make it possible to effectively chamfer a somewhat curved workpiece, and also allows a stopped chamfer to be started in the middle of the piece (although it will need to be finished by hand). The downside is that you have a very short sole, and no sole behind the iron. For most of the work this is not an issue, the side walls provide most of the guidance, however I found it easy to nose dive off the end of a work piece, resulting in the chamfer being larger at the very end. You have 2 tactics you can employ to combat this. 1. Don’t worry about it, and saw off the imperfect piece at the end. 2. Flip the piece around and create the “end” of the chamfer first before completing the rest.

I’ve taken a lot of pieces of wood in the last week and needlessly chamfered them as I’ve learned to use this plane effectively. It works really well, but the real joy of it is in the details. It looks like a particularly gorgeous vintage piece. Chris has done work as a gun restorer, and it shows in the wonderful chequering on the sides of the plane. This is as practical as it is decorative. Its definitely the grippiest wooden plane I own. You hands are absolutely not going to slip on that chequering.

The wedge and sliding box are made of east Indian satinwood. Given the sliding box is the sole, this notoriously hard wood is a great choice and going to have a long life. The unique design is eye catching, and the finish is immaculate.

When you first look at the sliding box arrangement, you wonder how on earth is the shaving getting of of this plane? The answer lies in a very small channel created by a delicate chamfer in the center of the end of the box. This allows shaving to escape after bring cut by the iron, and rise up through a channel in the box and wedge.

The chamfers on the body of this chamfer plane, are perfectly executed (of all planes, this calls for them). I feel these are the detail that makes this plane feel like an excellent vintage piece.

‘m delighted with my choice to acquire this plane. Its a curious mix of the classic combined with the innovative that few other makers approach. Given Chris has only just begun to produce and sell planes, I’m very much looking forward to seeing what he produces in the future. I’ve seen peeks of one or two that I hope my budget can stretch to when they go up for sale.

To keep an eye on Chris’s work, you can follow him at Cross Water Cottage Tools

The sliding box chamfer plane ready for use.

Just finishing up a chamfer. You can see the side walls bottom out preventing further cutting.

Front view. I love the satinwood.

Chunky shavings from toward the end of creating a chamfer.

The side chequering. Provides a fantastic grip.

You can see the sliding box projecting, the iron peeking out behind it, and a little shaving in the throat. When I first assembled the plane, I was confused by the wedge projecting out the bottom, then I realized as log as it was shallower than the sliding box, it did not matter.

The depth of the sliding box will correspond to the size of the final chamfer.

The disassembled plane. You can see the channel for the shavings to escape in the sliding box and wedge.

This little chamfer at the end of the sliding box allows shavings the space to escape between it and the iron.

The chamfer is so delicately done that you can barely see it from the side.

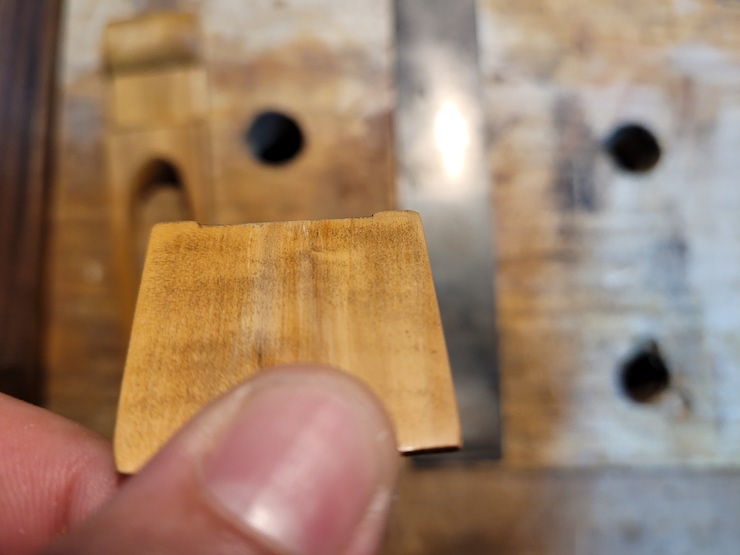

The wedge, sliding box and iron as I hold them before I slide them into the body.

The first string like shavings as a chamfer is begun.

Which quickly progress to more substantial shavings as the chamfer is established.

A chamfer in progress.

A mitre plane Chris Byrne is currently working on.

His exquisite router plane, deriving from the forms of musical instruments.

More work in progress