Restoring a Beading Plane

I have a few beads I want to put on a project, and as luck would have it, I came across some Irish beading planes on ebay that would do the job nicely. I selected a 3/16th and tried it out. As I got it, it did indeed cut a bead. The bead was rough, and the quirk (inside groove) part of the cutter was very proud of the sole when the rest of the iron was aligned, making it very hard to start the cut. So its time to fix it up.

So this is the patient, its in fairly decent shape.

H. McNeill where a Hardware store in Dublin, unlikely to be the actual maker. I have another beading plane made by Booth Brothers Dublin which is almost identical.

The boxing and sole are in good shape, Hopefully I wont have to do anything with them.

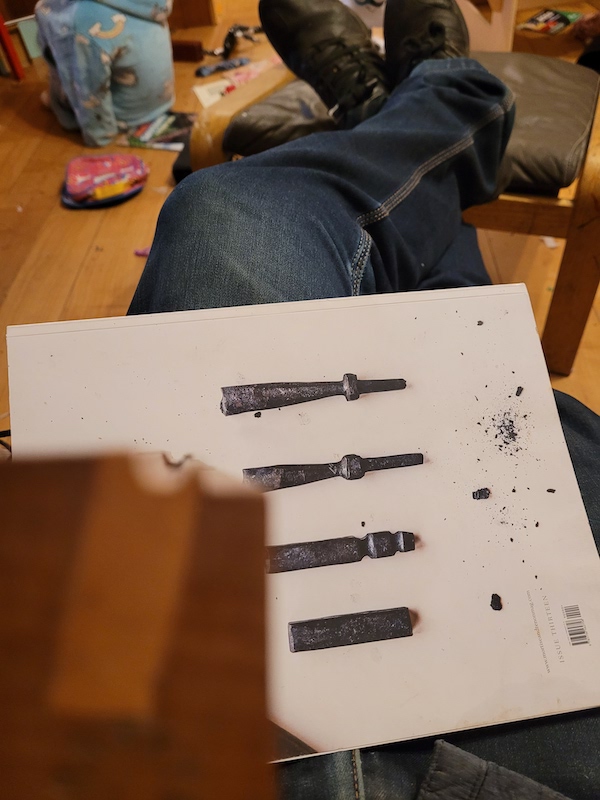

Sharp is everything, and the first step to sharp with any plane is to get the back of the iron sharp.

After 5 minutes on an Atoma 140 diamond plate. This is a pretty good result. Normally I would see relatively little progress and use some 60 or 80 grit sand paper to lap. That might not be necessary here…

Another 5 minutes and we are getting closer to the edge.

Another 5 and we have just about hit the edge of the left hand side.

Another 5 and we are most of the way up the quirk portion (top).

Another 5 and there is just a tiny bit of the quirk portion that’s not flat. So 25 minutes of lapping total, that’s pretty quick for a vintage iron. I’ll be reducing the size of the quirk portion, So I’m not going to worry about that, I’ll be removing at least that much.

2 minutes on a 600 grit Atoma diamond stone.

2 minutes on a 1200 grit Atoma diamond stone. I’ll be taking it a little higher, but I’ll wait until I have corrected the profile, that way the last grit can remove any burrs I create in the process. Time to put the iron back in and check the profile.

When you need to remove the iron in a plane like this, the easiest way to do it is to simply tap the end of the iron until it drops out of the bottom. Trying to back these off by striking the rear is usually slow, if it works at all. When you place it back in , apply pressure to the side of the iron as shown here before installing the wedge, that makes sure its aligned properly.

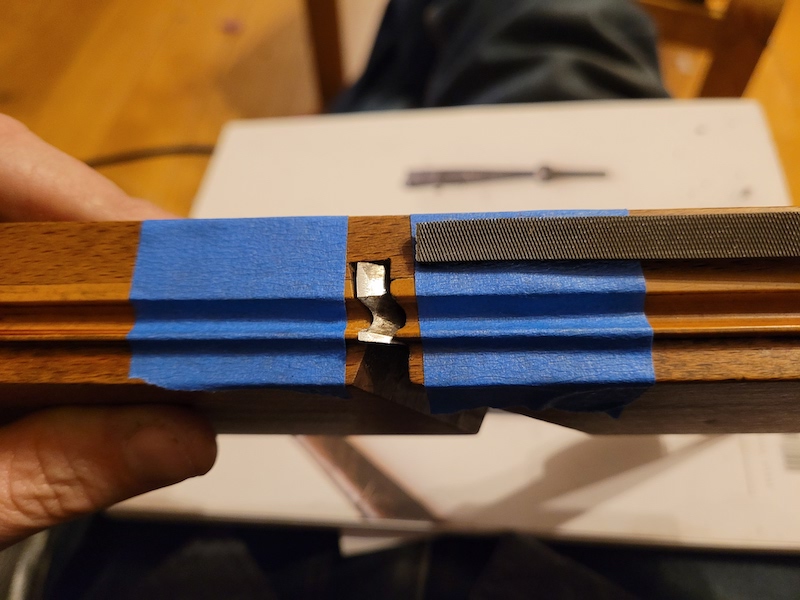

We can see the quirk portion on the right is very high, the left hand side and bottom of the curve is also protruding quite a bit more than the right hand side.

I started off by masking the sole and using a small file to work on the quirk portion. This was too awkward, I quickly removed the entire iron and just a large file to work on it.

The quirk is down quite a bit, time to finish lapping the back.

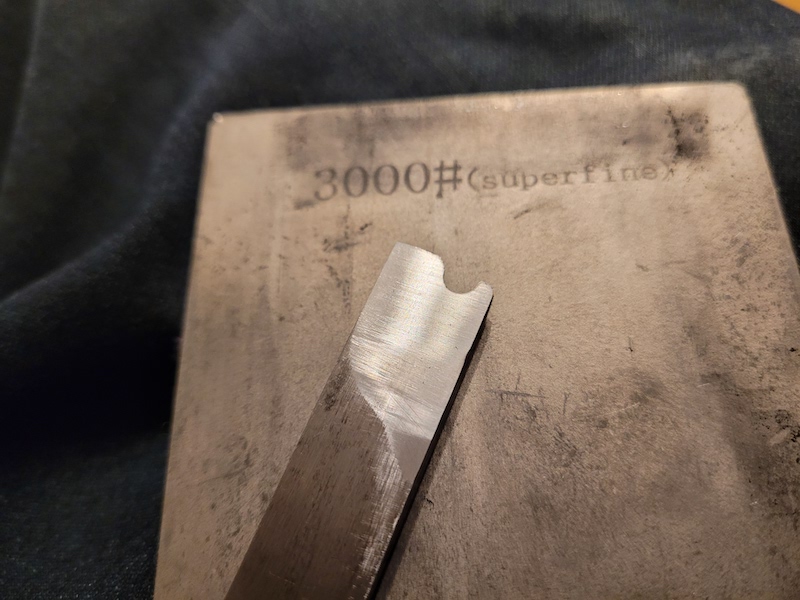

Finished on a 3000 grit diamond stone

My slip stone is far to big to work it

Found something that will do the job

A tapered diamond file can get in there.

Once I have worked the high bottom and side and evened them out, I refined the edge with a 3000 grit small oilstone rod. These tiny rods are very handy for jobs like this.

Free hand sharpened the quirk portion on a diamond stone.

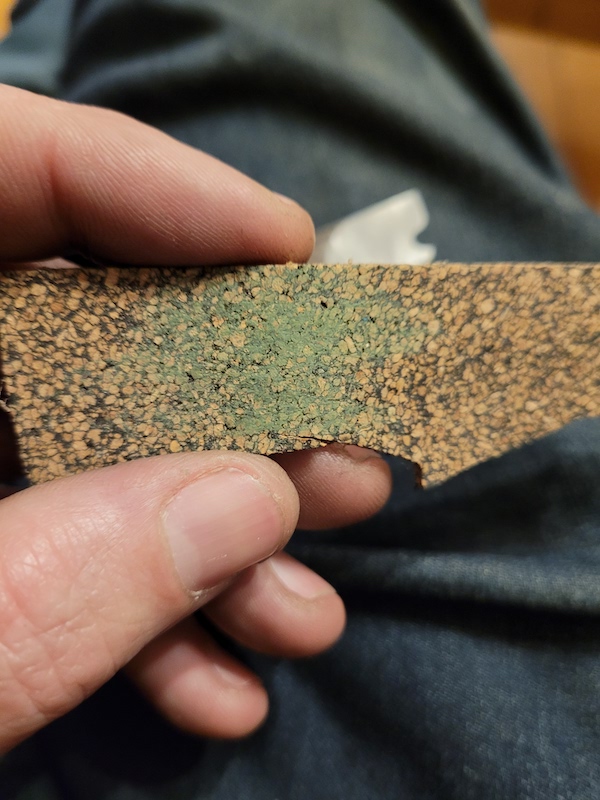

Some Chrome Oxide on a bit of crubber

And I can strop the concave portion of the iron. Now it’s time to test it out.

I grab a piece of scrap and put the plane to work. We have a side bead! It’s still a tiny bit rough in places, and the quirk portion of the cutter still feels a touch too high, but good enough for now.

The profile (on the right) is a good reflection of the iron

You can see the very start and end of the cut are a bit rough. When I use this in anger I’ll use an over length piece and only cut it to final size once the bead has been created. I’m not experienced enough with these tools to know if its just lack of skill on my part, if the plane needs a bit more tuning, or if this is just expected.