Tongue & Groove with the Stanley 45

I need some 3/8th inch tongue and groove boards for the back of my mini tool chest. I found my 45 here in Ireland a few years ago, spent a lot of time cleaning it up, and then in its box it sat. Only in the last few months have I actually taken it to wood. Now my problem is that Stanley never made a 1/8th inch tongue cutter for the 45…. I decided to take a chance and ordered the 1/8th inch tongue cutter for the Veritas small plough plane.

This is what you get. The part on the left is a chip deflector. It is only useful in the Veritas small plough. In the middle we have a small allen key which allows you to adjust the depth stop in the middle of the tongue and groove cutter. And to the right, the cutter itself. The small piece in the middle is an adjustable depth stop. As pictured it is set to full depth.

And here it is in the Stanley 45

Even the depth adjust slot works perfectly But there are still some problems for my project.

When you close up a Stanley 45 completely with the tongue and groove cutter fitted, guess how big the gap between the skates is? It just over 3/8th of an inch. The perfect size for my 3/8th inch stock to slide between. The Skates are beveled on the inside, and it cant go all the way through, but it can slip deep enough that your cutter dives deep into the stock.

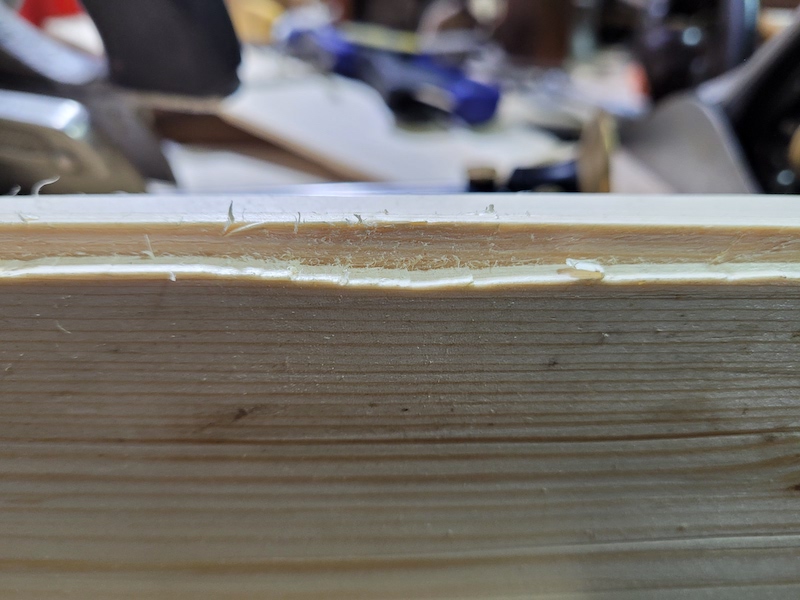

My first attempts to create a tongue on 3/8th inch stock where a bit of a disaster. Either my tongue was centred, and sooner or later the board slipped inside the skates wrecking the work. Or the tongue was so far off centre, the corresponding groove would have walls that where way too thin on one side. Pictured above you can see the results of the skate slipping off the side and the cutter nose diving.

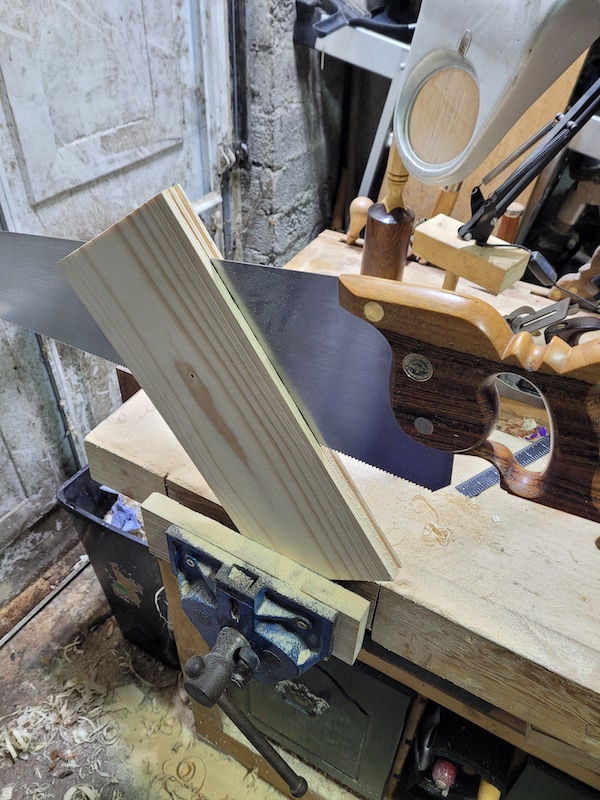

My first attempt to work around this was to put a sacrificial piece in the vice behind the piece I actually wanted. This sort of worked, but even with extra clamps on the side, every now and again the skates would force the two pieces apart, slide in between, and wreck the work.

I managed to get 3 pieces tongued and grooved, but to put it kindly, they where raggedy, uneven, with side walls on the grooves were too thin in places. I took a break and thought about it.

My eventual solution was to tongue and groove 3/4 inch stock, and then size down to 3/8th after that had been done. This worked well and was pretty easy going, that said, a few tips of tongue and groove with a 45

-

Use a work piece longer than your desired finished length. Even with the depth stop I found it very easy to nose dive at the end of the work, leading to a ragged shoulder at the end of the work piece. Have a few inches extra at the end that I don’t mind sawing off when I’m done makes for a less stressful operation. This was not as big a problem when grooving, but still a bit of an issue.

-

Use a work piece wider than your desired finished width. That way if you mess up to bad, you can just plane off the tongue and go again. Rip to width at the end. Once you have the tongue in, you have to go to final width before ploughing the groove.

-

You want your stock to be as straight grained as possible, and definitely no knots at the edge you are working. Particularly when using the tongue cutter, reversing the plane direction is not really an option.

Test fitting the tongues and grooves before I rip to size.

I spent about a week away from my workshop at Christmas. Came back and went to cut the groove for my tongues. I could not find the 1/8th inch cutter for my Stanley 45 anywhere. Its a tiny cutter, I’m sure its in my workshop somewhere, but I can’t of the live of me find it now. This led to a lot of fruitless hunting and frustration. So I started to think about alternatives. I eventually hunted out the cutters for my record 043, and looking at the 1/8th cutter for that, I thought it looked a lot like the 45 cutter.

So I have it a try, and it worked perfectly. Its a perfect match in size for the 1/8th tongue cutter. Given you can get a set of new 043 cutters for £13 from https://www.oldtoolstore.co.uk/ , if you are missing some of the smaller cutters for a 45 they are a great option.

Unlike the other 45 cutters, the 1/8th does not have a depth adjust slot, so the record really is pretty much identical to the stock 45 cutter. The larger sizes do have a depth adjust slot, so the record replacements are not quite as attractive for those.

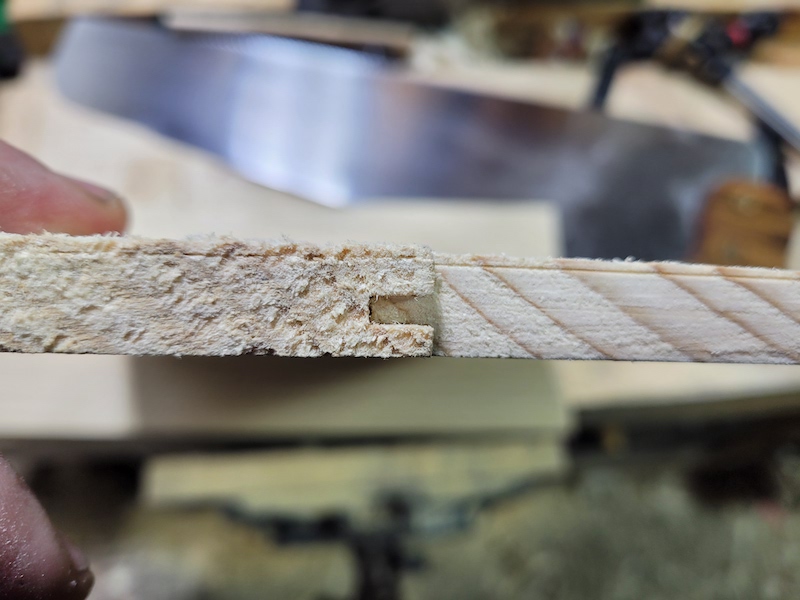

So, with tongues and grooves cut, I ripped my stock close to final thickness and then finished them off with a plane. I could not mark a line on the tongue side of the boards, which was a problem. I wrote one piece off when I wandered too far off and had to make a new one. Then I realized the side wall of the groove on the waste side made a fine line to saw to, set my marking gauge to that depth for the remaining pieces.

After resawing things are looking pretty good.

And after planing to final size, we have a pretty nice looking panel. Between the top board and the next board on the left you can see a bit of a gap where the cutter nose dived. As the pieces are wider than I need them. I can just saw this off when I go to fit them to the back of the chest.

So that’s it for tonguing and grooving for now. Anyone else know of any other sources of 45 compatible cutters?