Cross Grain Rebates in Pine

This week I have been fighting to make cross grain rebates with my record 778. I’ve used it before to make long grain rebates where it performs beautifully. But cross grain rebates are an entire new ball game.

There have been many things I expected to challenge me while working on my mini tool chest, a rebate was not one of them. My first attempt was ugly as hell, tons of tearout, a horrifically mangled piece of wood was the result. I set out to troubleshoot the plane and see what I could do. Part of this is down to working in pine, its not very forgiving when it comes to this kind of work.

First stop was the Nicker. When you start a cross grain rebate with this plane, you first draw the plane back several times to allow the Nicker to score the wood and sever the fibers. The Nicker on this plane was not as sharp as it could be, and more importantly, was far too long. I have no idea why the Nickers are provided so long, an untouched brand new one if simply sharpened would leave you running the plane back and forth for quite some time before it cut deep enough to allow the sole of the plane to make contact.

I took it to a diamond stone and worked it until it projected a bit more than 1/32nd of an inch from the sole (it could probably stand to be worked down even a little more). You sharpen this a little like a gouge. Work it in an arc on the stone to create the bevel, and then polish the back.

Simply getting the Nicker sharp and down to a sane depth made some improvement in the quality of the rebate. The side walls where much crisper, but I was still seeing a lot of tear out. I checked the iron and discovered it was a little out of square. I corrected that with a honing guide, and again, saw a tiny bit of improvement.

The rebates I’m creating are cosmetic, they are intended to give a raised panel look to the drawer front at the bottom of the chest. As a result, they are only around 1mm deep.

The following process gave me just about acceptable results.

-

Use a marking gauge to score the wood at the end of the rebate (the end you will be planing towards) at your desired final depth. This will help prevent breakout.

-

Score the wood by drawing the plane backwards several times to allow the Nicker to do its job. Concentrate on keeping the fence in contact with the work.

-

Make one or two very shallow cuts (on a deeper rebate, no need for these to be shallow, you would work close to depth, with only 1mm of depth in my case I’m almost there)

-

Remove the Nicker at this point, otherwise it will leave an ugly scar

-

Set the plane to the thinnest shaving you can. Just a little above only creating dust

-

Plane to depth

This still was not perfect, but a tiny amount of sanding and I got an acceptable finish.

I’m struggling to get a crisp rebate wall, I’m finding fibers at the top are getting worked up and making it kind of raggedy, I’m not sure what the problem there is. As best as I can tell its happening due to the planes iron being a little proud of the side, but the Iron on a rebate plane needs to be a tiny bit proud of the side, so the fix for this is still a puzzle for me.

Once I got this down, I set about rebating my workpiece … and it was a disaster. I made the mistake of sizing my door to the opening before rebating, so it was no longer quite square, and the resulting panel looked like I was staring at it after downing 8 pints. In the trashcan it went, and I’ll try again next week.

What I really need here is a skew rabbet plane. The skew in theory does a better job of creating a decent finish cross grain. Record made the 712, 713 and 714, essentially skewed 778 planes in different width’s, but these are rare and expensive. Veritas sell a modern Skew Rabbet plane, but its also a touch pricey. Maybe next week I’ll give my Stanley 46 a crack at the job and see how it gets on.

The results of my first attempt. Not pretty.

Nicker set to a bit more than a 32nd

The record 778. I love this plane for long grain rebates. Cross grain, its proving a challenge.

My work holding solution for the job

I used a marking gauge to cut the fibres on the end of the side of the board I’m ploughing towards. Helps prevent some tearout. I find having a physical reference for setting depth handy. So both the planes depth stop and the marking gauge are set to the depth of this ruler (its a really shallow rebate).

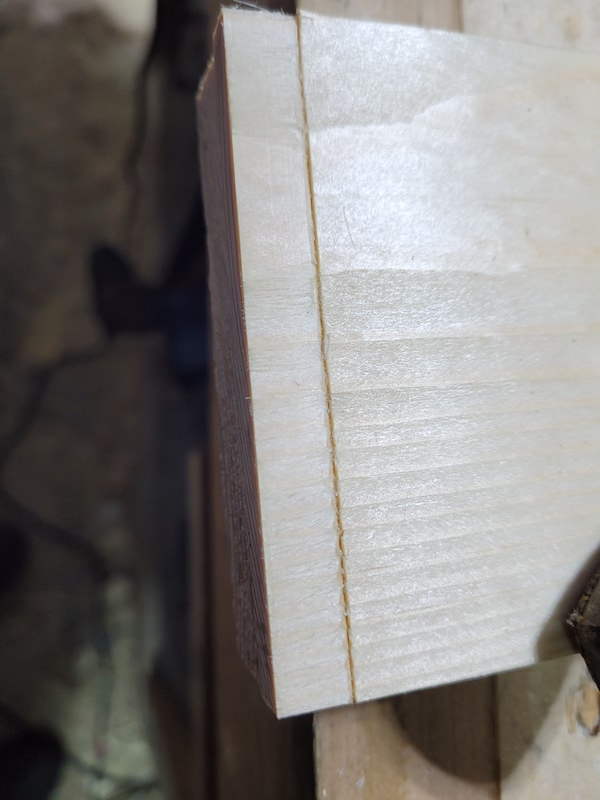

The severed fibres after using the marking gauge.

About as good a result as I could get. This is after a little light sanding. Still not happy with the wall of the rebate. The uppermost fibers have been lifted up in places.

This would be a great tool for the job. The record 712. A skew version of the 778. A bit too rare and collectable to be a practical option though. Record also made the 713 and 714 (same plane, just wider).

The Veritas Skew Rabbet plane. Probably the best modern plane for the job.