Vintage vs Modern plug cutters

The eagle eyed Andy Brown spotted a pristine vintage plug cutter for a brace on the vintage tool shop and pointed me at it. Being an incurable addict when it comes to brace bits I snapped it up, and it arrived this week. As it happens I already have one vintage plug cutter, so I decided to finally try it and my new acquisition out. Then for fun, I tried some modern plug cutting bits in my brace.

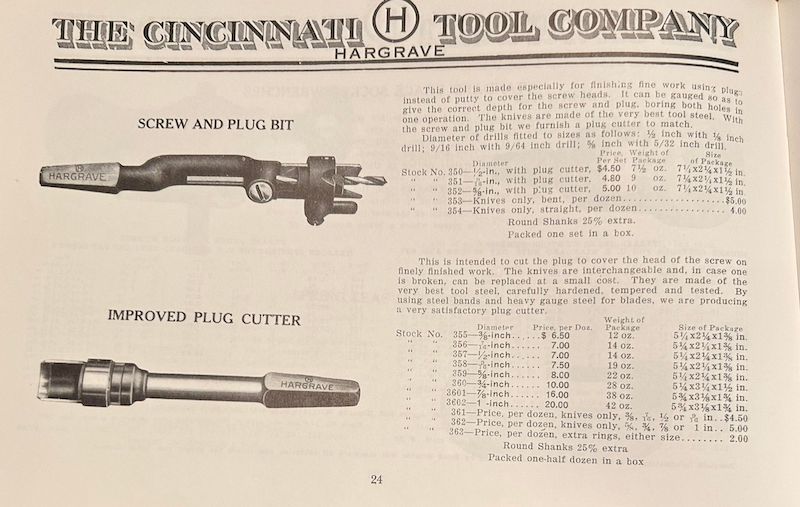

The 3/4 Cincinnati Tool plug cutter cuts a slightly tapered plug of wood out of a board. These where typically used to conceal nails and screws. The process would be 1. Drill a shallow hole the size of the plug. 2. Drill the hole for the nail/screw and drive it. 3. Glue in the plug and then flush cut/trim to size. Having a tapered plug is an advantage, as if the widest part is slightly larger than the hole, you can drive it in to get a seamless fit, like a cork in a wine bottle.

Starting the cutter neatly is a little tricky, but not impossible. I found putting my weight on it to get it to dig in and then working it back and forth slowly allowed for a relatively clean start. Its not essential in any case. Given the plug will be trimmed after fitting in most usages, a little bit of tear out at the top is no big deal.

Chester Spier was kind enough to send me a photo of the catalogue page for the tool. Its worth noting the cutter on this is replaceable, and they sold replacements in packs of 12. That would suggest the cutter is somewhat fragile, so I will be taking a great deal of care. I doubt I’ll be finding a pack of 12 any time soon. I’ve linked to a video below of the tool in action. It does not cut particularly quickly, but it also does not take a large amount of effort to use.

Then I moved on to my second vintage cutter. This has no makers mark. It worked just as well as the Cincinnati, but with one odd detail. I found I would get to a certain depth and then the plug would break out. I cannot quite figure out if this is a feature or a bug. I cut 4 plugs with it and got the same behaviour each time. On the plug side, this means you don’t need to drill all the way through, or cut in to release a plug. So you get a plug quickly and with less work. On the downside, if you are going to plug a lot of holes, having a single longer plug that you can repeatedly drive in and cut off is a time saver. I have no idea if its an oddity of this cutter, or a deliberate design feature.

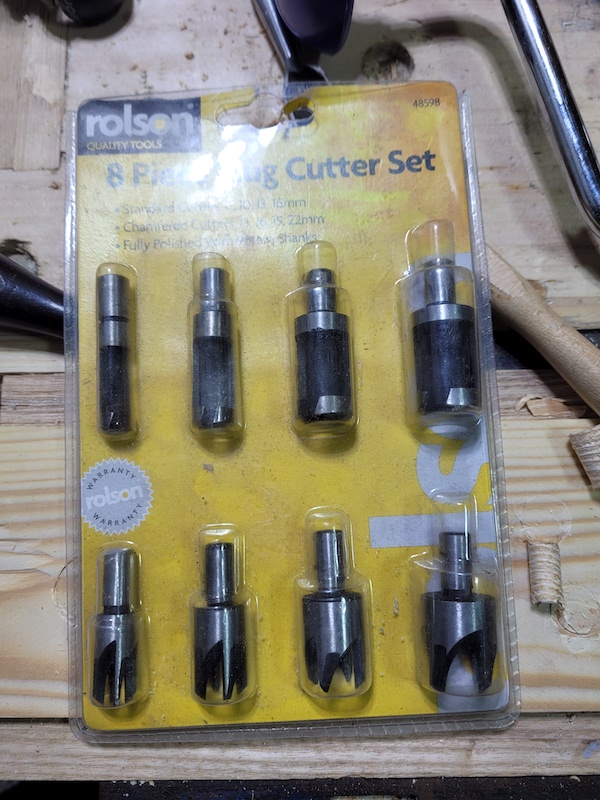

Finally I moved on to some modern plug cutters I’ve had for quite a few years. These are designed for use in a modern powered drill, so I was curious to see how they would behave in a brace. First off I tried using a modern 4 jaw faithful brace to drive the bits, thinking the 4 jaw brace would do well with a round shank. And it failed, it simply could not keep a hold on the bits. I’m not sure if this is a problem with 4 jaw braces in general, or this specific (cheap) faithful brace. In any case, I tried it in my North Bros 2100 2 jaw brace, and it could hold them just fine.

The tapered modern plug cutter worked pretty well. I had to apply more downward force than with the vintage cutter, and needed to remove the bit once or twice to clear the hole. But the finished plug was actually neater than anything I got from the vintage bits.

The straight plug modern bits where very difficult to use in a brace. I gave up on trying to use the largest size in my set, the amount of downward force required to make progress was exhausting, moving down to a small size, it worked just fine, again with a lot more downward force required and removal for waste clearing required. The straight plug cutter bit also required using a punch to remove the plug when done.

So my final verdict would be… You don;t really need a vintage bit if you want to cut plugs with a brace. The modern tapered cutters will work just fine, if with a little more labour. The modern cutters are cheap and widely available, I think I picked mine up off Amazon at some point.

Videos of the bits in Action:

-

Vintage Cincinnati - https://youtu.be/V4738GyOfSM

-

Unknown Vintage - https://youtu.be/C5oJjDYuXkg

-

Modern Tapered - https://youtu.be/oYwQSQK4r34

-

Modern Straight - https://youtu.be/WRi4XpqzAIg

And finally, this video shows deck plugging on a ship being carried out with modern tools

https://www.youtube.com/watch?v=ohIiwRy6mlc

This and other diversions are archived at https://blog.vintagetoolpatch.com, if you would like to write one, reach out and let me know!

Two models of vintage plug cutter.

Side profile of the Cincinnati Cutter with Removeable Blade .

Cincinnati box

With a little practice, a fairly neat start can be obtained. I find going back and forth and gradually extending the arc a little more each time gives the best result.

The unmarked plug cutter did this every time, breaking out the plug at about the same depth. I’m not sure if this is a feature or a bug, or if it would be repeatable in a different timber.

The only mark on the unbranded plug cutter

Plug cut with a modern tapered cutter. Difficult to start cleanly, but otherwise worked well in a brace.

Plug cut with a modern straight cutter. The first, larger size I tried didnt really work in a brace, I could not exert enough downward force to get it to cut. Smaller sizes worked fine.

Modern plug cutter set.

Several deck doweling bits. These would be used when attaching decking planks. After a smaller hole had been drilled for nailing or bolting a plank, these would chase that hole, carving a larger hole for a plug to be inserted in to conceal the nail/bolt.

Advertisement for the Cincinnati bit. Now I want the screw and plug bit as well!