North Brothers Braces

I love braces. I often buy weird bits just to play with them. My scrap bin is full of wooden Swiss cheese. Something about drilling with a brace brings me joy. From bringing kids into my workshop, I know I’m not alone. They generally gravitate to either saws, or drilling holes with braces.

This week I rounded out my brace collection by spotting and snagging a 14 Inch North Brothers 2101 brace. Time for me to celebrate the king of hand braces.

The Yankee brace is pretty much everything you could ask for. The ratchet is sealed and dust and weather proof. The ratchet housing is brass, which again contributes to corrosion resistance. The 2100 are Nickel plated, the 2101 are chrome plated. The handles are not wood, although some have oxidized enough to take on a brown colour. The actual material appears to be some sort of vulcanized rubber. The ball bearing chucks are incredibly smooth, on one of mine when I first picked it up I thought the ratchet was broken. It was so smooth I could not hear it in operation. North Brothers where acquired by Stanley in 1946. Some folk claim the pre Stanley braces are superior. I’ve yet to find any practical difference between pre and post Stanley braces. If they changed anything, it wasn’t much.

Possibly the only weak point is that the internal lubricant has been known to harden and jam the ratchet. Isaac smith has a great guide to disassembly and cleaning if you run into that problem.

http://www.blackburntools.com/blog/yankee-2101a-brace-disassembly-and-cleaning/

In day to day terms, this brace holds just about every bit I throw at it. When I was playing with plug cutters recently, I switched to a modern 4 jaw brace to try and use a modern round shank plug cutter. No dice, after a second of operation the bit would slip in the chuck. So I grabbed my North Brothers 10 inch brace. It worked flawlessly. Bits do not slip in this brace. The ratcheting operation is insanely smooth. Every one of these braces I have has worked perfectly on arrival.

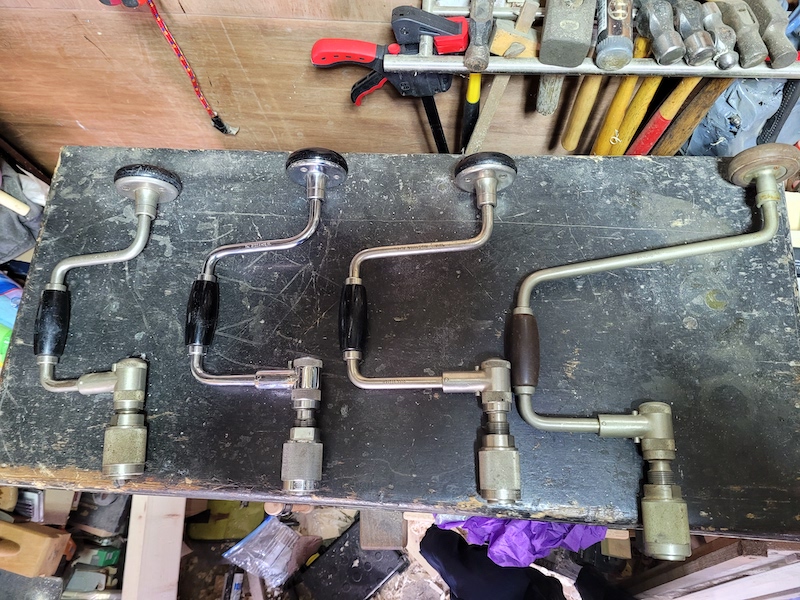

I currently have a 8” 2101A, a 10” 2100A, a 12” 2101A and a 2101-W Whimble brace. The Whimble does not appear in any of their catalogues, But obviously exists. There are reports of a 6” model (again, not in the catalogues), but I have never seen one.

The Whimble is a crazy looking brace that allows you to drive it with both arms at once. It is for pure raw power. There may be someone out there who can drill straight and true with a Whimble brace. I am not that person. If I’m trying to drive a 2 inch bit through hardwood. I’ll get it started with my 12 inch brace. Once I’m heading in the right direction and have a little depth, I’ll switch to the Whimble to power through.

So what’s the difference between the 2100/2100A and 2101/2101A? The 2100 series were more expensive, but other than the plating, I have yet to hear a clear explanation of why. In use, I don’t see a difference. The “A” seemingly indicates an improved model, but again, I’m not clear on what the improvement was. The 2101 series is more common, and was a standard tool for Bell Systems linesmen. Many of the braces are actually stamped Bell System. I have heard rumours that the braces where built to Bell’s specification on a cost plus contract, which may explain why its so heavily engineered compared to the typical brace.

Now that I am done singing the praises of these wonderful braces I imagine you are wondering why the hell the crazy man thinks he needs this many braces. Well I don’t. For the most part, a single good 10 inch brace should do anyone just fine. If you use braces a lot, it becomes handy to have several to hand with your commonly used bits permanently mounted in them. Just saves a little time. When it comes to size. If you are drilling very large holes, your arms will thank you for the larger braces. The larger the brace, the bigger the lever, the more power you have to turn a large bit. That comes at a cost. The wider the brace, the slower it is to turn. So brace size is a power/speed trade-off. If you are using very small drill bits, you are better off with a 6 or 8 inch brace. You can get the job done faster. I keep my braces in a rack where I can quickly grab the one that feels like the best size for the job at hand. Ultimately I have this many braces because I love a nice brace.

For anyone who wants to dive down the North Brothers Brace rabbit hole, here are a few useful references:

http://www.sydnassloot.com/brace/northb.htm

http://georgesbasement.com/galootsales/Sale02152007/YankeeBraces.htm

https://www.georgesbasement.com/fs2101a.htm

https://archive.org/details/YankeeTools1931

From left to Right. 8” 2101A, a 10” 2100A, a 12” 2101A and a 2101-W Whimble. The plating on the 10 inch 2100A has survived noticably better than the others.

My brace rack. Well above head height, I can quickly reach up and grab the right tool for the job.

The Yankee chuck beside a more typical brace. The sheet size alone shows there is a lot going on.

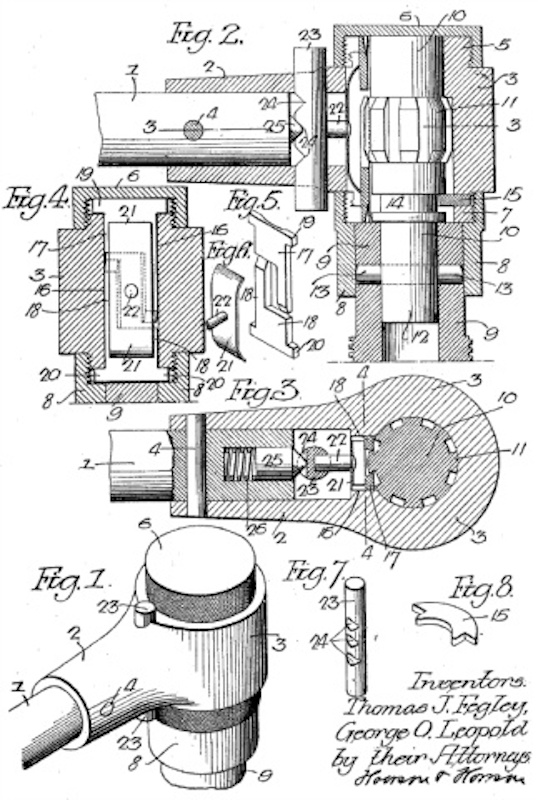

Patent diagram for the chuck.

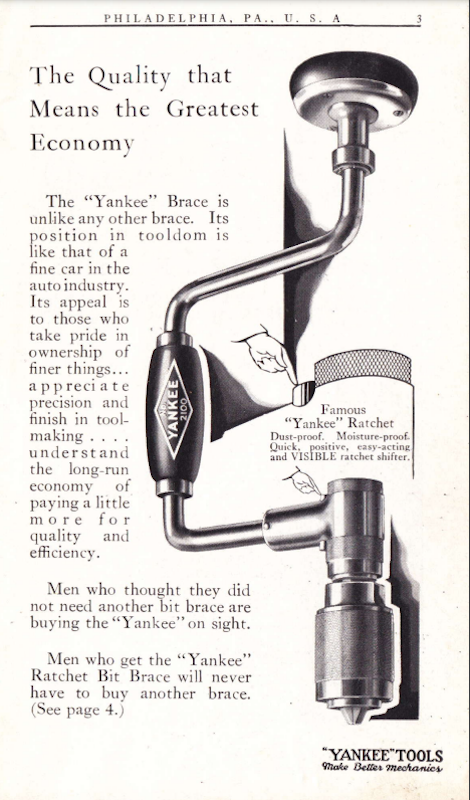

Advertisement boasting the weather proof qualities of the Ratchet

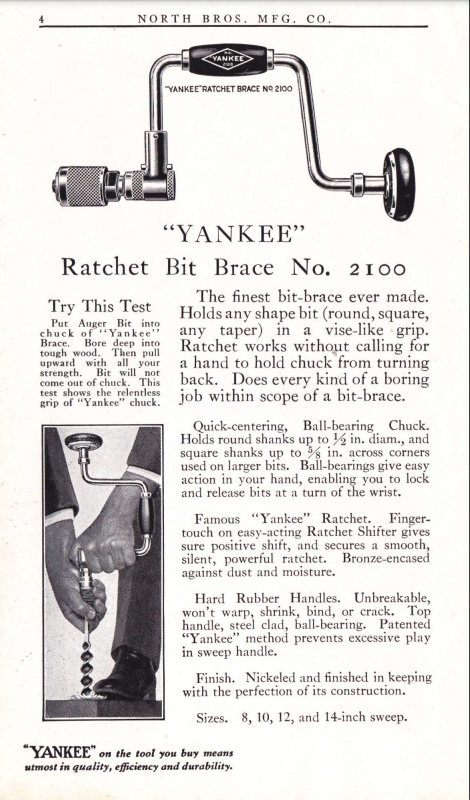

Another Advertisement mentioning the Bronze casing.

The Whimble brace, powerful, but not for accuracy.

This stripped brace shows the brass housing