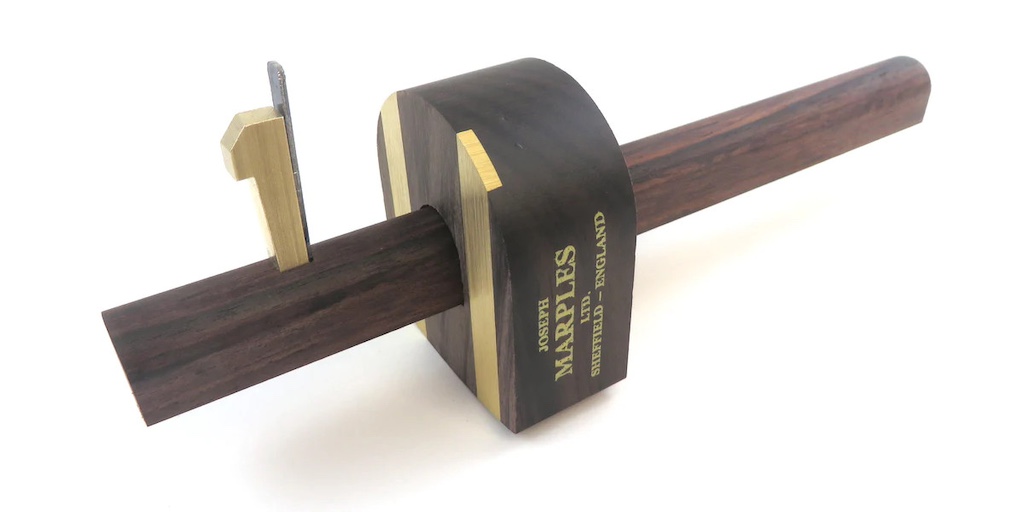

Marples Slitting Gauge

Until now I’ve always used either pin or wheel makring gauges. I was out buying some wood when I spotted that the store has some very pretty Marples slitting gauges (Marples call them a cutting gauge, but in my head, they are slitting gauges), and decided to pick one up on a whim.

The gauges are rosewood of some sort, with brass wear strips, and a knife style cutter held in with a brass wedge. Marples make cheaper versions with less brass and plainer woods, but its already a very cheap tool, so I opted for the pretty one.

Straight off the shelf, the cutter is not close to sharp enough, and created a ragged gouge in the wood rather than a clean line. About 5 minutes work on my stones and I had it working cleanly. Its a very thin flexible cutter, so if you are not comofortable free hand sharpening something like that, it may not be for you. The typical honing guide is not going to be much help.

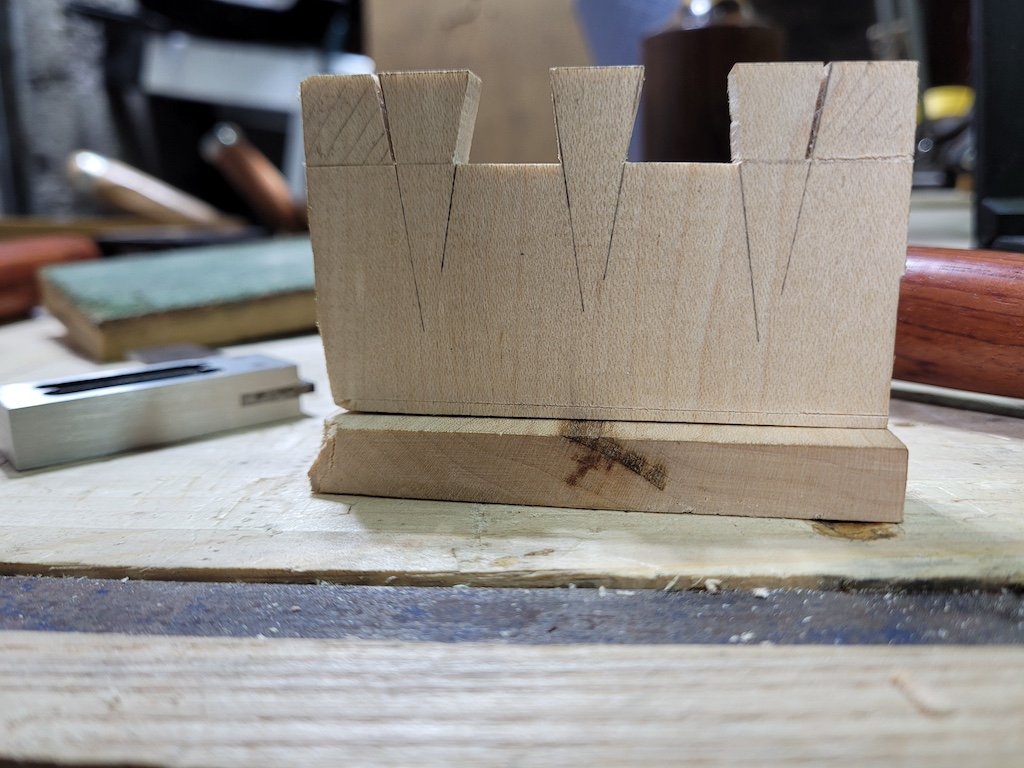

The cutter is flat on one side, and beveled on the other. In use, you will want the bevel on the waste side of the line you are marking. To put it through its paces a little, I dovetailed some hard maple. Initially, I had the cutter extended way too far out. It made it very difficult to get a clean straight line. Once I figured out my mistake I dramatically shortened the distance is extended from the post and all was well.

The key advantage of a gauge like this for dovetailing, is that its far easier to mark just the waste portions on the dovetail. With the gauge slightly angled, I cant start the cut right where my saw cut ends, and then when I’m finished I dont have any work to remove gauge lines from show faces. I found marking have the width of the waste from one side, and then half from the other to start with worked well and prevented me from overshooting. The gauge cut quite deeply, so once the initial line had been established I could make a few more passes to deepen it and the depth of the initial line made it wasy to stop at the right place.

I noticed while using it that my gauge has a slight crack rising from the socket that holds the knife and wedge. Did it already have a flaw when I bought it that only showed up when I drove the wedge back in, or did I drive the wedge too hard? I don’t know. It shows no sigh of growing in use so I’m not too concerened.

Overall I like the gauge. Its a little more trouble than my veritas wheel gauge, but its much easier to create a really deep line, which is fantastic for registering you chisel in for the final chop when dovetailing.

It is a very pretty gauge

It is a very pretty gauge

Starting the tip of the knife at one side of my dovetail waste

Starting the tip of the knife at one side of my dovetail waste

The crack in the upper post, good chance that is my fault.

The crack in the upper post, good chance that is my fault.

A close up of a marked waste line

A close up of a marked waste line

After chopping. I had not dovetailed anything as hard as maple, so my penultimate cuts where not quite close enough to the waste line resulting in driving back into the gauge line a little, not a terrible result though.

After chopping. I had not dovetailed anything as hard as maple, so my penultimate cuts where not quite close enough to the waste line resulting in driving back into the gauge line a little, not a terrible result though.