Toy Katana

I had a very difficult client recently. They wanted the piece made today, had very specific requirements, and not much of a budget. My 5 year old wanted me to make him a Katana. I usually spend a long time figuring out how I’m about to approach a project, and work pretty slowly. Lots of practice cuts. Lots of test pieces. It was fun to just knock something out in an hour for a change.

I grabbed the closest piece of pine I had, and just had at it. I left a little bit of work at the end for him to help me finish off, and had a very satisfied customer. He rewarded me by immediately attacking me with it. Such is life. See the photos below for some quick hack job woodworking that I’m pretty pleased with.

Made any weaponry for the tiny psychopaths in your life? Stick some photos in the comments so we can all admire them!

The random pine board. I grabbed a long ruler and quickly sketched out the shape of the sword.

Two quick rip and crosscuts and the “blade” is roughed out.

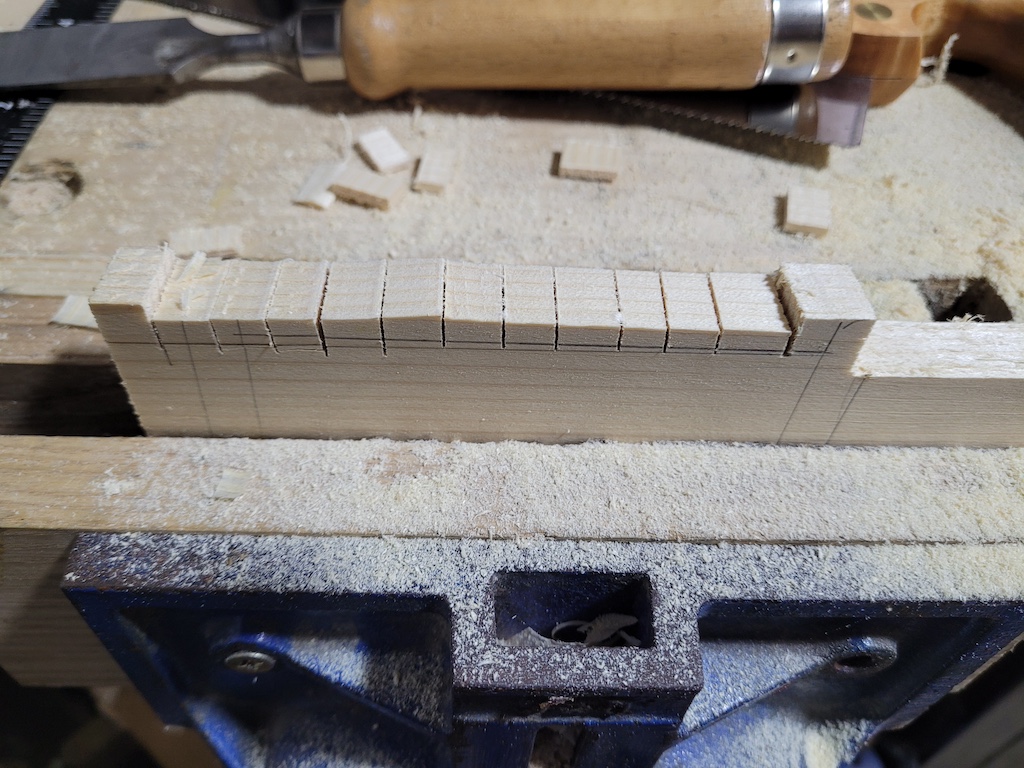

A bunch of relief cuts either side of the handle. You want the last relief cut on either end to be relatively close so you don’t have to take a big hit to free it. I spent a lot of my time on this project just trying not to (a) Snap the blade, (b) accidentally snap off the guard, (c) accidentally snap off the pommel. As you get closer and closer to getting finished. The project gets thinner and thinner.

Grab a chisel and start knocking them out. The guard and pommel are not very substantial, so I start in the middle and work to each end. As you approach the end to take the last chunk out take care, it would not be difficult to accidentally knock the guard or pommel off.

Working down the other side.

Done. Its not very flat and not very square. This does not matter at this point. Later I’ll refine it a little with the shinto rasp. It’s ideal for the job as you cannot really get a plane or spokeshave from end to end.

Now to shape the tip of the blade a little. I started off with a spokeshave, but really, that’s a lot to spokeshave off. It was going very slowly.

Back to the chisel we go. Its not a very substantial piece of wood. I locked it low in the vice to it could take the chopping without snapping.

Refined a little with the spokeshave, and now it looks like the end of a katana to me.

Time to start putting a bevel on it. Back to the spokeshave. I put it high in the vice and use pull cuts. You cant do the entire length with the spokeshave, but you can get pretty close. The chisel shinto rasp will be used to bring the section close to the pommel down.

Getting there, the knot and reversing grain around it are a bit of a pain.

Time to start shaping the handle a little. I make some stop crosscuts above and below the guard, and above the pommel. This lets me chisel and spokeshave the sides of the blade down so the pommel is out all the way around.

And its back to the chisel. I work down to the depth of the stop cut at each end, taking care not to knock the pommel or guard off.

Then hack out the rest quickly with the chisel

Switch back to refining the bevel. I alternate between the rasp, and very light cuts with the spokeshave. As its gets thinner, the risk of snapping grows. At times I support the tip on my stomach as I work it to reduce the chance of snapping

.

Time to hog off the rest of the material I don’t need on the handle.

The blade is now thin enough that its hard to work with the spokeshave without snapping it, so I switch to the shinto rasp to even out the bevel

A few minutes work and its actually starting to look a little like a katana

A medium modellers rasp makes short work of smoothing out the handle.

Not too bad other than the blocky handle.

The client uses a rasp to round off the corners

And then a little sanding to make it comfy

And we have a weapon for the tiny nutter to clobber me with

He didnt do a bad job on the handle!

And of course, if you are willing to put a bit more time and care in, you can make something truly wonderful, Like this treasure Myrto Malouta and her son made!