Tiny Square

Some woodworking tools are really jewellery with an excuse. No saw needs a handle made of spalted maple or have a delicate lambs tongue. There are people out there who can cut better dovetails than me with a cheap big box hardpoint saw. There is no natural law that states that handle planes shall be adorned with rosewood, but my god its pretty. I think it may come down to something simple. People who make things, appreciate pretty well made things. I begrudge no one their pretty tools, especially when I have a little work shop full of them.

Once afflicted with tool magpie syndrome, there are some things you buy just because you want to have them, admire them and hold them. You may have come up with a reason why you “need” that tool, why it would be useful and practical, but deep down you know its a rationalisation, and the decision to add to your tool hoard was made long before you came up with the excuses.

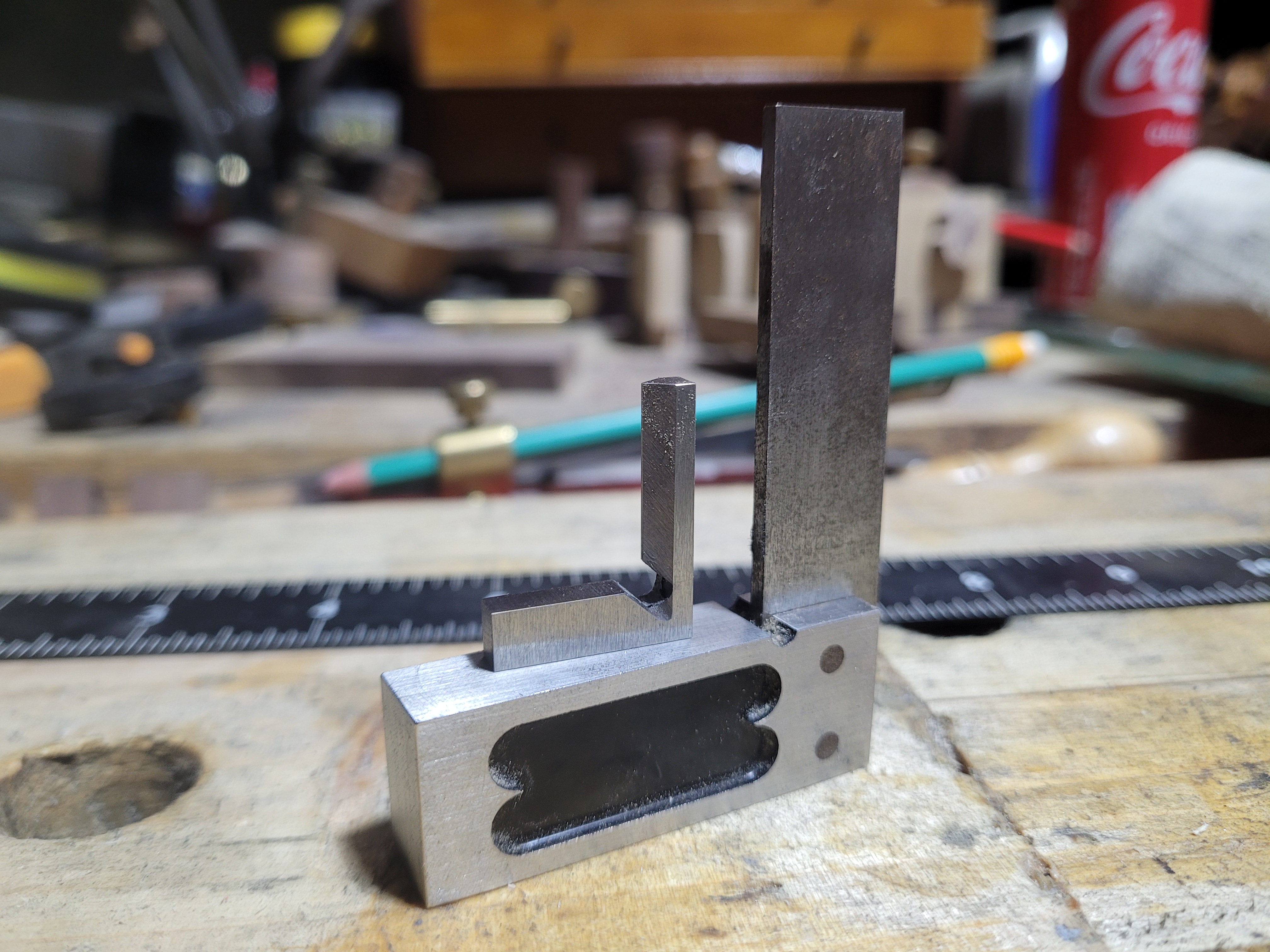

My latest shameless addition to my hoard is a very tiny square. I have come up with uses for it, but ultimately, I bought it because I wanted it, nothing more or less. It is tiny. It is dwarfed by my previous smallest square. It is my teeny tiny baby square and I love it.

Made by Kinex in the Czech republic, it measures just 20mm * 25mm. That is just less than 1 inch on it’s longest side. It is no toy. It manufactured to DIN 875/00 standard. That would be the German Institute of Standardization (“Deutsches Institut ür Normung”). The 00 indicates this is made to the highest of the 875 standard, which if I am reading it correctly means it accurate to within 3 microns on the long side, and 2 on the short side. For those not used to thinking in microns, a typical bacterium is in the 1 to 10 micron range… It can stand on its own side without having to be held, and one edge is bevelled.

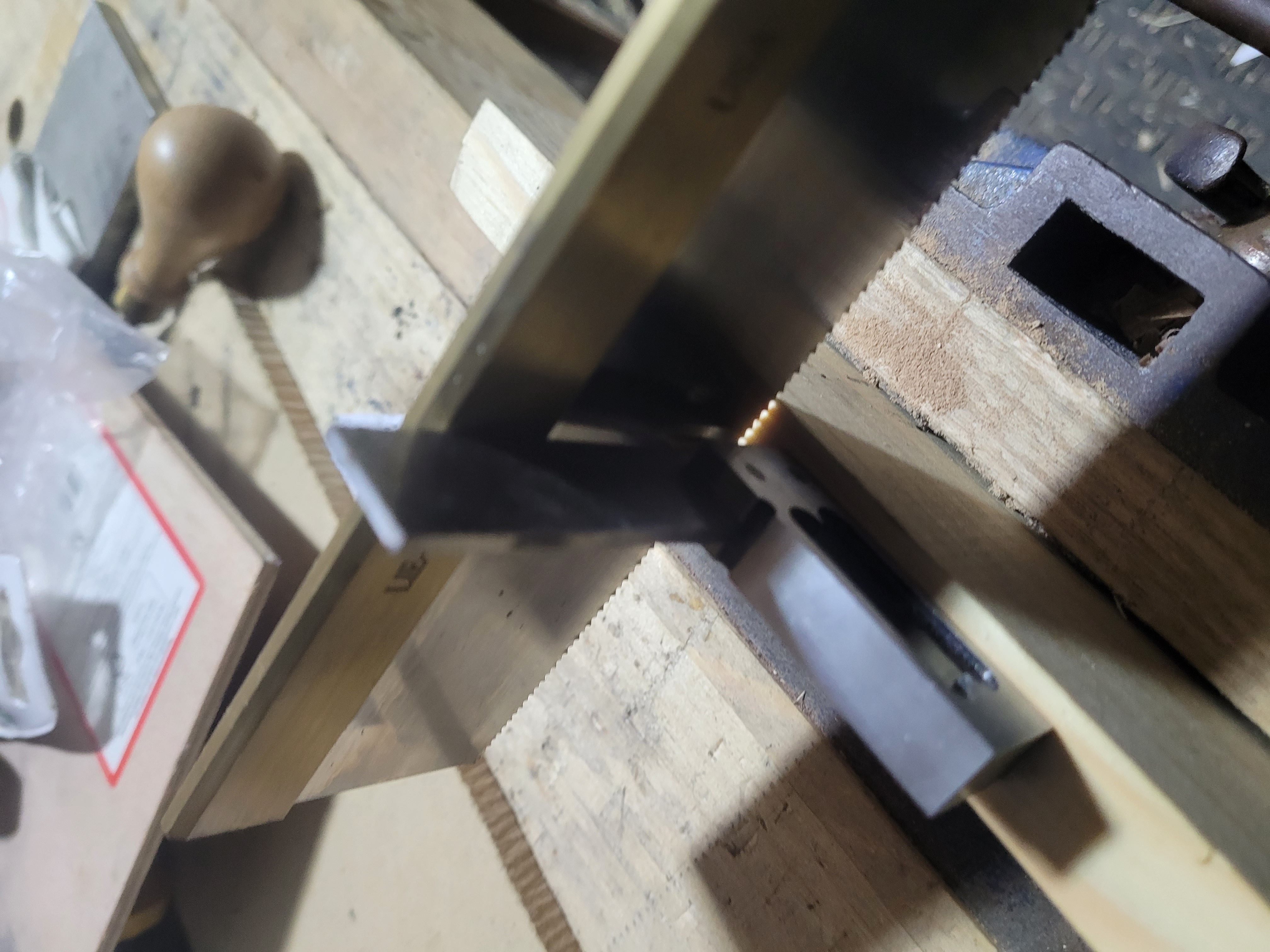

What are my micron thin justifications for this tool? The first one I managed to drag up was practicing my saw cuts with back saws. I sometimes hold a square up to the saw to check my perception of square (which is very poor), in an attempt to train a good sense of 90 degrees into my brain. My previous smallest square. The Union 222, is too tall for the job. It runs into the back of the saw, not the plate. This tiny thing does the job just fine.

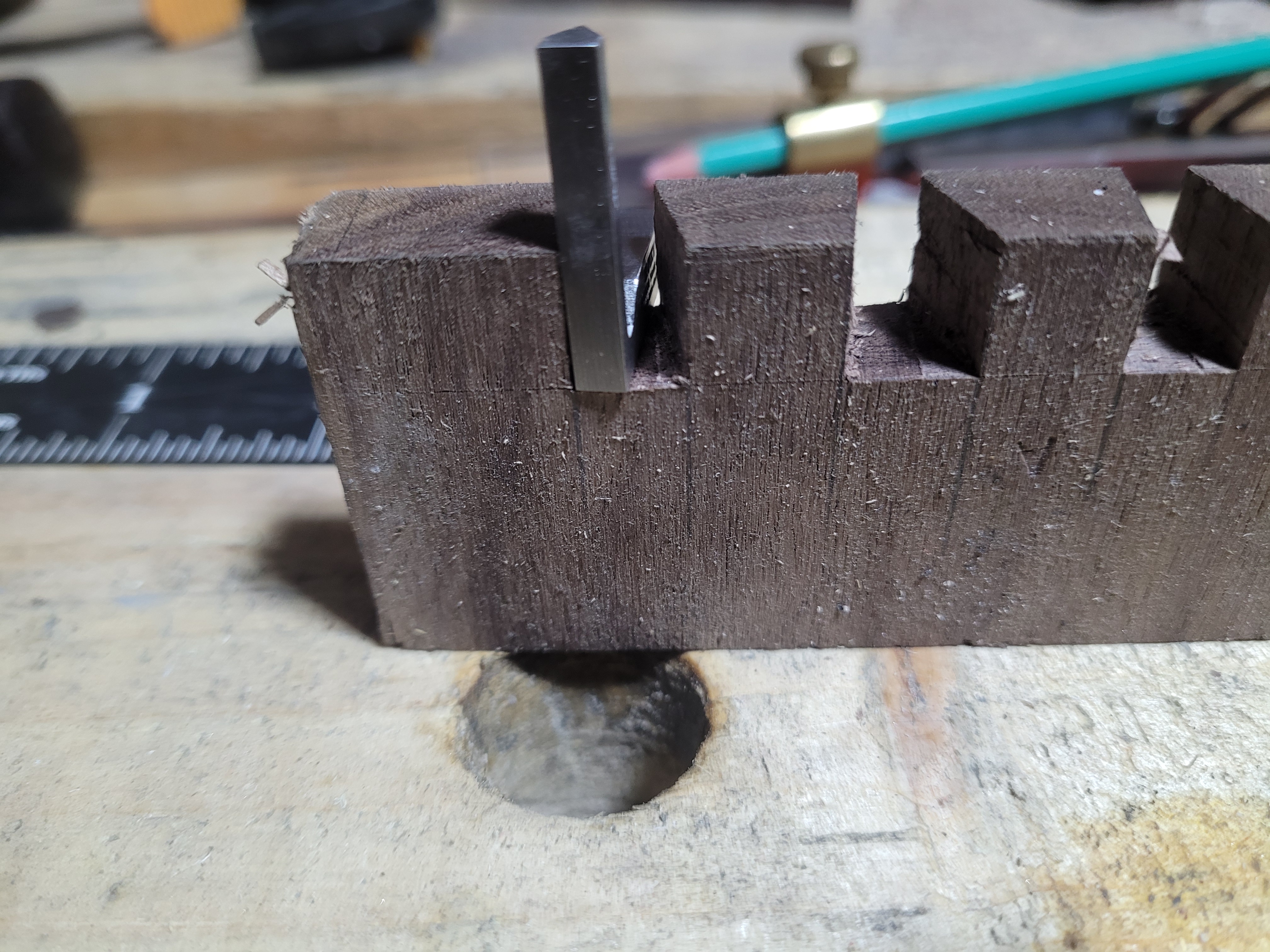

The second is dovetail checking. It is so small it can side in the pin sockets of all but the tiniest dovetails. Allowing me to slide it around to check for bumps and humps and the straightness of the tail walls.

And that’s it, it is tiny, it is cute, and I love it. You can find it here https://shop.kinexmeasuring.com/en/knife-edge-square-kinex-25x20-mm-din-875-p9002270c22c189/?filter=7. I have no connection with Kinex whatsoever.

No, I don’t have abnormally large hands.

No, I don’t have abnormally large hands.

Less than an inch on its longest side.

Less than an inch on its longest side.

Dwarfed by a union 222, which I consider a small square.

Dwarfed by a union 222, which I consider a small square.

Fits inside a small dovetail

Fits inside a small dovetail

Checking for square before cutting with a backsaw was not ideal with the 222

Checking for square before cutting with a backsaw was not ideal with the 222

No problem with the Kinex

No problem with the Kinex