Poor Man's Tail Vice

I have no real tail vice and 90% of the time I do not missing having one. I do however work on a lot of small/thin pieces, and when you are trying to plane them down to thickness, I often find myself wishing for a way to hold a really thing piece in place for planing.

I was watching Epic Workshops Rasp cabinet build, and the solution sped by. Its only visible for a few seconds. You can see it here: https://www.youtube.com/watch?v=4ETNRIFdFDM&t=566s

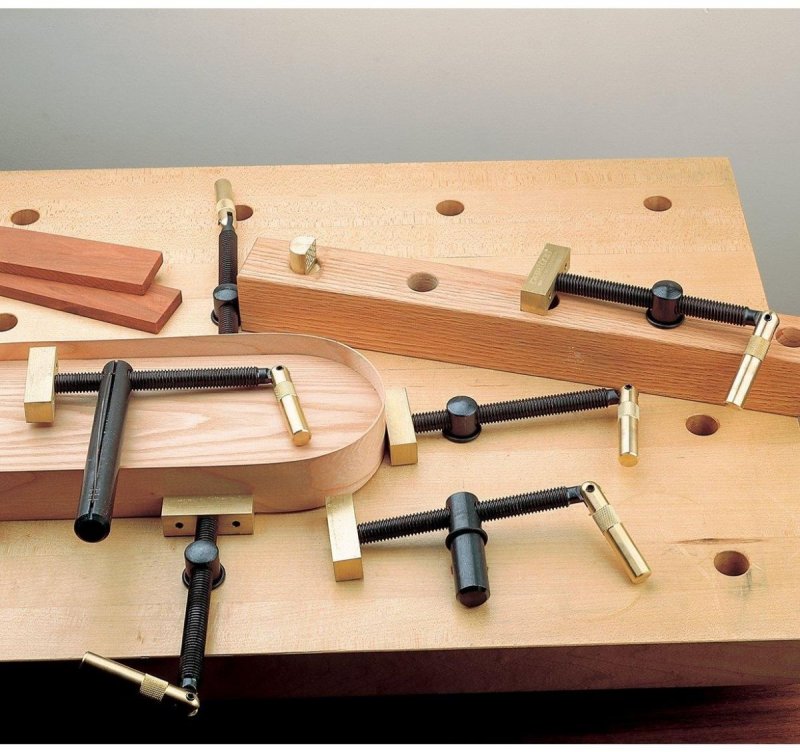

He combines two tools into a perfectly serviceable tail vice. At one end of the work piece, he is using a Veritas Bench Blade. This small clamp sits in any 3/4 dog hole. It uses a cam lever to clamp. Its range of motion is pretty small, but that does not matter thanks to the second part. It is a $20 tool on the Lee Valley Website, and also comes in versions for 20mm holes, can attach to a T-Slot track. There is also a “wedge lock” version that allows it to lock in horizontal holes.

He takes a plastic speed square, and drops it’s ridge in his face vice. This is the genius part. As you can quickly slide the speed square back and forth in the face vice, a 12” square gives you nearly 12 inches of range. That means two dog holes give you all you need to clamp anything less than 2 feet long. I keep the square under my bench, and the Bench Blade in my tool well. I can set up or tear down in seconds.

The Surface clamp is only 5/16th tall, the square is only 3/16th. So for anything above 5/16th I have a tail vice solution. Anything much thinner than that is going to flex when clamped, for ultra thin pieces like that, two strips of masking tape superglued together is a better solution.

I’ve been using this solution for a few years now. Not as solid as a real tail vice, but its 90% of the functionality for a fraction of the cost and work of obtaining and installing a traditional tail vice. You can watch a short demonstration of the setup in use at https://www.youtube.com/watch?v=pe1N1p2T2TU.

I added to the setup with a Veritas Wonder Pup, for taller workpieces it provides more and sturdier clamping force.

Check out the photo’s below to see what the setup looks like in use.

The Veritas Bench Blade, drops in a dog hole and clamps via the cam lever. Only 5/16th of an inch tall.

This is what the setup looks like in action.

The ridge on the speed square let’s you drop it quickly and easily into the vice. Works OK as a general purpose planing stop as well.

The square is only 3/16th tall, no point in going thinner as the Bench Blade is a little thicker.

The Bench Blade is only 5/16th tall at the clamp, a little taller at the rear. If that is a problem, you can stick a thin piece of scrap between the blade and the work piece to get clearance to plane.

For meatier work pieces, I use a Veritas Wonder Pup to clamp, its a lot taller than the blade (5/8th vs 5/16th), but clamps a lot harder.