Bench Dogs

I like 3/4 inch round bench dogs. My bench has been described as looking like “swiss cheese”. Any time I think “I could use a bench dog there”, I just grab a brace and a 3/4 inch bit and make myself a new hole.

The holes get used for bench dogs, holdfasts, wonder pups and probably a few things I’m not thinking of right now. Some people lovingly craft beautiful looking bench dogs. I regard them as disposable objects. I put them together very quickly, and do not care if they get lost/battered/cut whatever.

I buy a length of dowel roughly 3/4 inches wide. I don’t care if its a millimetre or two off. I put a bullet catch in the side. The bullet catch allows the dog to grab the inside of the hole in the bench so I can adjust their height to just where I want it for the job at hand.

I can see from the inside of the dog holes that the bullet catch leaves them a little more worn than it would otherwise be, but after years of using them, I have yet to rag out a hole to the point where anything, including holdfasts have a problem with them. Check out the pictures below to see my quick, and very dirty process for knocking out a new holdfast. It only takes a few minutes.

Some people like square dogs. They provide a bigger flat surface for work to register against. Its too much extra work, both on the dog and the hole for me. I fairly regularly butt a piece of work up against a single round holdfast and plane it without problems. So its not a big enough advantage.

Some people make holdfasts with a top larger than the hole to provide a square surface to register against. I prefer the advantage of being able to adjust the height. I was planing down some stock to 1/4 inch last night. I could set my dog to 1/8th high and get on with it.

Some people cut away a section of the top of the bench dog to provide a flat. Maybe even lining the flat with leather. Too much work for too little gain in my book. Just use the round dogs, you will not miss it.

Just about the only trick is to ask yourself “what is under there” before you dirll a new dog hole. Am I about to drill into something structural? Am I about to break through and hit my vice screw? A quick look under where you are about to sink a dowel hole is always worth it.

See the pictures below for my quick and brutal dog making process. It only takes a few minutes.

The ingredients. 1 5 inch length of dowel, 3/4 inch thick or less. One bullet catch. This one is 12.5 mm. 10mm is actually a better size, but its what I have to hand.

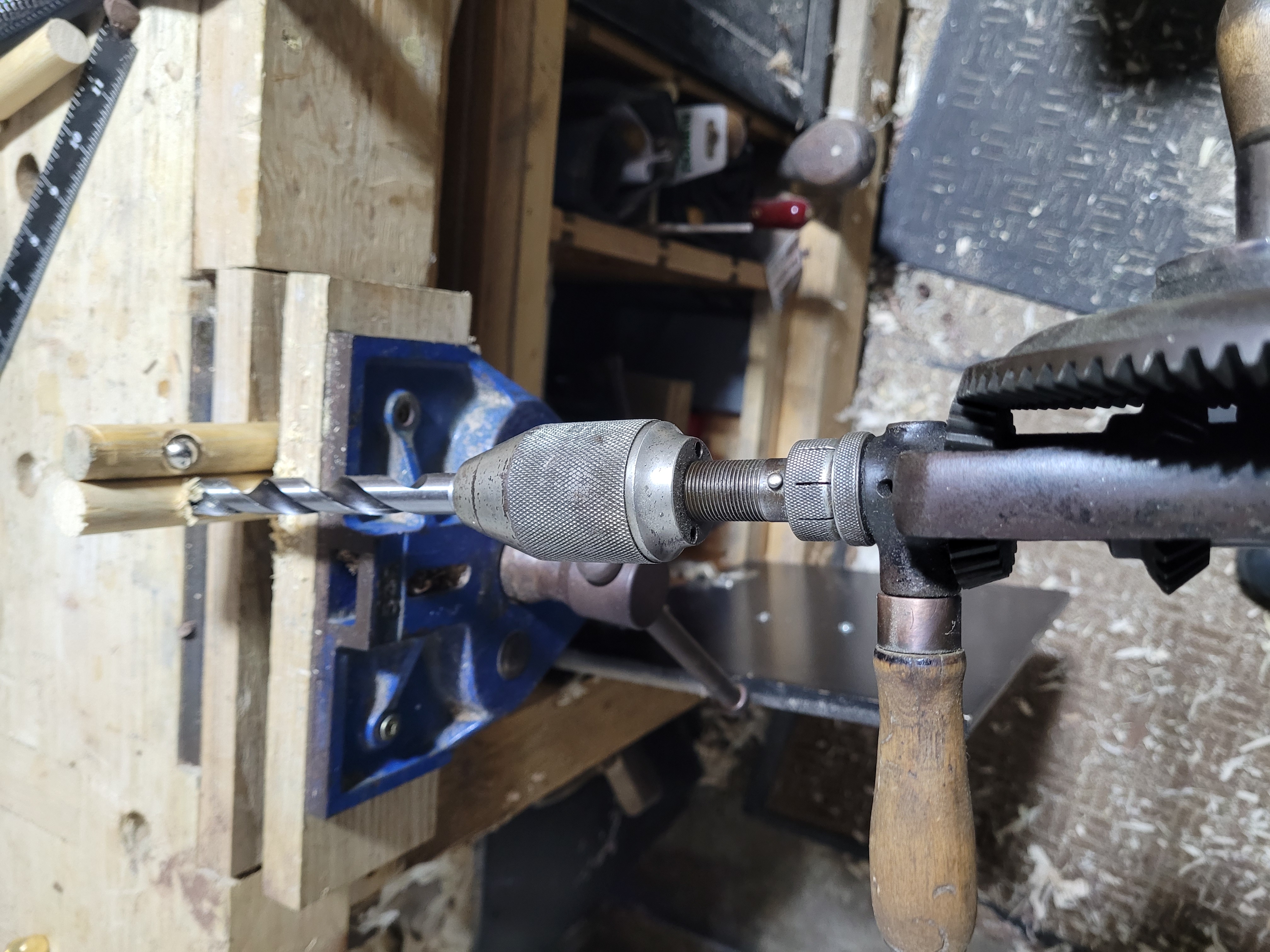

My 12.5mm bit will not fit in an egg beater, so out comes the breast drill.

I grab an old dog and line it up with the new one in the vise, and drill in at roughly the same spot. Exactly where to drill depends on your bench. You want it low enough to be able to have enough dog sticking out of the bench, but high enough that you can sink the dog below the bench surface without it falling out. If you are not sure what position to go with. Just make one, it only takes a few minutes, and trying to use it will tell you everything you need to know.

For these ball catches I drill almost all the way through the dowel. you can see the hold from the one on the left, and the wood breaking out at the back of the one on the right. I just clean off anything protruding with a chisel. It may look like the dog is going to be very fragile with this honking great hole in it. But I have never had one snap on me.

The drilling is pretty forgiving. A little off center? Doesn’t matter. Drilled all the way through? The lip on the ball catch means it will still work. I’ve done it.

Not a very pretty hole, but good enough. Take off any splinters with a chisel and get on with it.

If you put your ball catch in now, you will find it does not fully seat. The lip keeps it proud. It will catch on the dog hole and not work.

See, no way that is going in.

So I grab my microplane

And hog off material until the rim is low enough. Nothing special about the microplane. You could do this with any rasp, file, or just chisel it out.

Now the rim is just inside the dowel

And with a little push, down it goes. It will hold at this depth.

Or lower. I leave them just below the surface when not in use. The ball catch is not even glued in. If I wreck and batter the dog too much, I can just pop the catch out and use it in the next one.

Finally, you can watch a short video of the bench dog in action here

Finally, you can watch a short video of the bench dog in action here