A long ripsaw

I love a long rip saw. I often build small projects and want 1/2 or even 1/4 inch thick stock. Very few options to buy pre-dimensioned stock at that size, so I generally end up re-sawing and ripping a lot.

Something I truly hate is just feeling that I have hit the ideal rhythm with my saw when I pull back a little too far and the saw hops completely out of the cut. I’m pretty lanky, so my arm has a fair reach, and with shorter ripsaws this happens to me a lot. My primary ripsaw is a nice Disston D8, but it was cut down a bit in its past life, presumably to fit in a tool chest lid.

I was browsing through some tools and went, oh look, a D8. The thumb hole in the handle is the saws signature. I know other makers made thumb hole saws, but I generally only see them in the hands of dedicated saw collectors. Something about the thumbnail struck me as off, so I clicked in to have a better look.

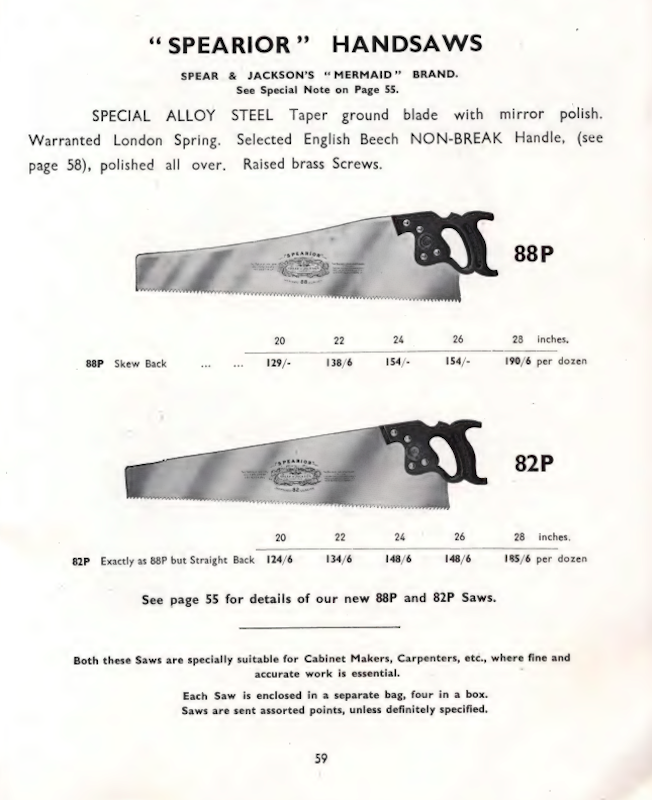

It was in fact not a Disston saw. But a Spear & Jackson Spearior Mermaid P88. These may, for all I know, be common as dirt. But it was my first time seeing one. The etch was in great shape. The saw in fact looked like it had seen little to no use, so I snapped it up.

I’m glad I did. The plate is 28 inches long. Not the saw, just the plate. 28 glorious inches. From end to end the entire saw is about 30 inches long. I’ve ripped and re-sawed a few boards with it, and never once have I had the saw come out of the cut from being pulled back too far. I’m in heaven. That said, I think a decent 26 inch would suit me just as good.

I hear a lot of differing opinions on thumb hole saws. Their opponents say that that using the thumb hole encourages bad mechanics and the cut is bound to wander. They are not wrong. I would never start the cut while using the thumb hole. That said, once the plate is well into the cut, I’m not above using it. Yes you tend to drift a little. But just keeping an eye on the cut you can see it happen and correct every so often before it gets out of hand. I’m happy to trade the increase in cutting speed for a ever so slightly less straight cut.

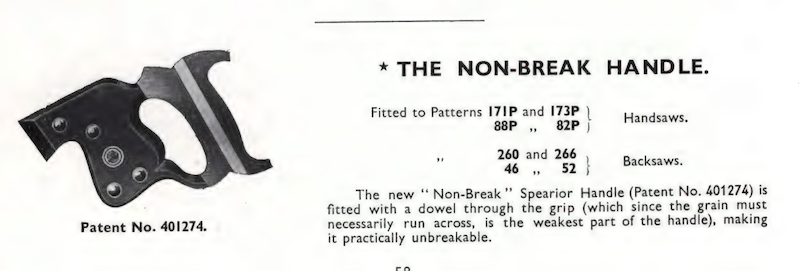

The P88 also has a “non-break” handle. This means they have a dowel through a section of it. I’ve never broken a saw handle. I was not aware they are so fragile that this could be necessary. I’m assuming this is just a marketing oriented boondoggle for now.

If, like me, you have a long reach, try a 26 or 28 inch saw. I think you will like it.

28 inch plate, 4 1/2 tpi, its a big saw.

28 inch plate, 4 1/2 tpi, its a big saw.

A nice crystal clear etch

A nice crystal clear etch

And a pretty fancy medallion

And a pretty fancy medallion

The thumb hole up top gives a comfy place for your left hand to grip and impart some downward force when ripping. Its a lovely saw, that I feel is somewhat ruined in its looks by the ugly “non-break-handle” stamp.

The “non-break” dowel end.

The other side of the handle for the curious

The P88 in the 1939 catalogue - https://archive.org/details/spear-and-jackson-catalogue-e-6-1939/page/54/mode/2up

The P88 in the 1939 catalogue - https://archive.org/details/spear-and-jackson-catalogue-e-6-1939/page/54/mode/2up

What the 1939 catalogue has to say about the non-break handle. I’m not sure I buy it. What are people doing with their saws that the handles are breaking?