Chisel Handles

Well, Sean put the call out, saying he wanted distractions - so that maybe over the festivities he could lose himself in a cloud of his own sprout and stout gas, and who’s to blame him for that? Well, I have been thinking about writing up my chisel handle technique - I think we have done it before - but here is a much more modern and updated method. Positively professional!

For me, chisel restoration is immensely satisfying. Far more than planes, or saws - although they are also great - there’s something about making a chisel handle and fitting the iron and ferrule and getting it all spot on. And, I get to play with my lathe, which is definitely my favourite thing to do. London pattern handles have the added bonus of needing some plane work too - two for the price of one! My other favourite thing is getting a glassy smooth surface on a piece of wood with a hand plane.

Check out the pictures below to see exactly how I do it!

So, here is the chisel I found in a big box of tools, it’s an I & H Sorby and I’d hazard a guess at early C20- possibly late C19 - happy for an expert to tell me more info here. It’s a whacking great thing, an inch and a half wide at the business end, and it tapers to one and three eights at the back, and it’s very thin - an eighth of an inch at the tip and three sixteenths at the base. This original (I assume) boxwood handle has definitely seen better days - so I figured I’d give her a new one. I decided to replicate the original as closely as I could - just for a laugh. What japes.

I took some measurements of the original. The Mitutoyo calliper that I patched from Chris Godwin is a diamond tool, far far more accurate than I would ever need, but at least I look professional as I’m doing it!

This is the blank I chose to make the handle - I had already turned to size and planed two faces before I remembered to take some photos. Essentially to measure the octagon bit, you measure the diameter on the original point to point, and then multiply by .92 to give you the diameter flat to flat. Then just cut a guide line on the lathe, at each end of the blank, to the required diameter and plane down to it.

An adjustable bevel set to 135° and a square are very important to get the octagon dead on. Although in my research - which is by no means exhaustive - I am yet to find a London pattern handle that is exactly square and all angles correct - but I guess, if it looks octagonal enough, then that’s enough. It’s not joinery we’re doing here, and you can’t see all the angles at once, so what really does it matter?

Facets all cut - two things to remember when you’re working in boxwood - The Blunt chisel and the card scraper - both are your friend. Box tends to have some squirrely grain, and it can tear out as soon as you look at it. Thankfully my scraper game has been fantastically Upped by the recent purchase of a Accuburr - thanks to Adam Pace - again the patch to the rescue!

I didn’t have a ferrule that was exactly the same size - but this one inch OD is spot on for width - and if I were a bit better metalwork wise I could cut it down I suppose - but I kind of like the longer ferrule - gives a bit more support and looks more balanced aesthetically on the handle. Purists will say I should have taken the original ferrule off and reused it. But those self same purists can fuck right off. My shed, my rules.

Get a rough guide for the tenon bit to go in the hole, and cut the tenon on the lathe. I have already drilled the pilot hole - 3mm - on this blank, and the live centre fits right into the hole and makes sure that the ferrule is spot on centred to the tang.

Once it’s fitted you can get to turning the handle

If you get a catch and bugger it up, as you might well see on the video, you can re-plane and scrape the spirally damage off… you might even let a swear out or two. We don’t make mistakes, we simply make smaller pieces than we first intended. Once I am happy with the shape and everything is set I sand up to 400g paper, and then on to shellac to finish.

I dip in thin shellac, three times, with a bit of hanging around drying time in between. Cup hooks in the tang hole help a lot. This one is a bit longer than my little jar - so I dragged the finish up the handle to the ferrule with a bit of kitchen roll.

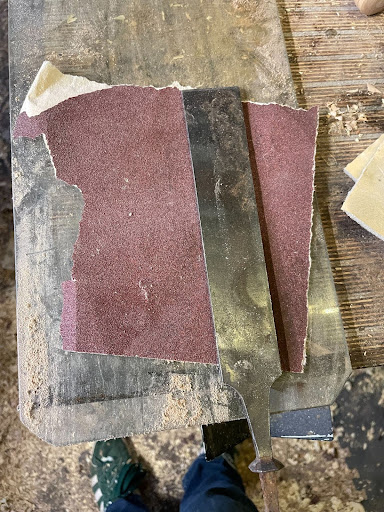

The chisel iron needed a little clean - there is some pitting on the face - but that won’t affect the cutting edge. A piece of glass and a series of sheets of sandpaper gets us to where we need to be. I have a Pro-edge machine too, so I use that to establish the bevel, and then on to the diamond plates a la Paul Seller’s technique for the final sharpening.

Odies oil and a kitchen scourer for the final finish - I do like Odie’s oil - but it is hella expensive - and I think Parrs is just as good. Odies was just the first tub that came first to my hand when I was at the finishes shelf. Rub on, leave for an hour or so, and then buff off with a soft cloth. Easy peasy

Regardless of what you might have seen on chisel based FB pages - there is deffo more than one way to skin a cat. I drill the pilot hole on the lathe and then drill out the hole for the tang with a power drill and increasing width bits with shallower cuts, and I use the tang as a bit of a reamer to make sure its spot on.

Then just hammer the handle home with a soft faced chisel hammer.

And that ladies and gentlemen is that. I have just looked through these photos again, and you would have thought that I would clean up before a photoshoot wouldn’t you? But no, filth and mess abound. I am a poor tidier, this much is certainly true. But its astonishing how I know exactly where things are on the bench, even though there’s crap everywhere! Imagine what I could do if I kept a tidy bench, as my mother would have said - if you had some brains you’d be dangerous! In the kitchen the first thing I drilled into commis was to clean as you go and to keep a tidy bench and a clean board. I guess I should have taken some of my own medicine!

And so, there you have it, a brand new shiny handle for a brand old chisel. Ready, I’m sure, for another hundred years or more of work. If you like the chisel - it’s on the patch this very minute - you could go and bid it up.

I do hope you’ve enjoyed reading my nonsense, and thanks for making it this far. Go and treat yourself with a festive christmas sherry or two. And have that last mince pie, it’ll just go to waste else.

Happy christmas all, see you in the new year.

Cheers W