Headboard Batten

During covid my kids took to using our bed as a trampoline. There was not much else to do, so I never had the heart to stop them. Now its just a thing they do a lot. It is a miracle there is a spring left in the mattress. Eventually the inevitable happened and they snapped one of the battens that hold the headboard on to the bed. Fixing that up made for a nice quick project over Christmas.

I can be a little obsessive when it comes to my woodworking. The chair from my October class is still not ¨complete” as I go over it with a fine tooth comb looking for tiny scratches and dings. Sometimes it can be fun to just knock something out quickly. This is one of these projects. It will be completely hidden once it is doing its job. It can be scratched, wonky, all sorts of insults. I took great pleasure in never checking for square and doing the bare minimum of finishing work. That also meant I had no hesitation getting the kids involved. Its a simple little bit of work. Even if they destroyed it starting over would not be a big deal.

To see the step by step check out the pictures below.

These are the battens from the headboard. Pretty simple. A few countersunk holes and two slots.

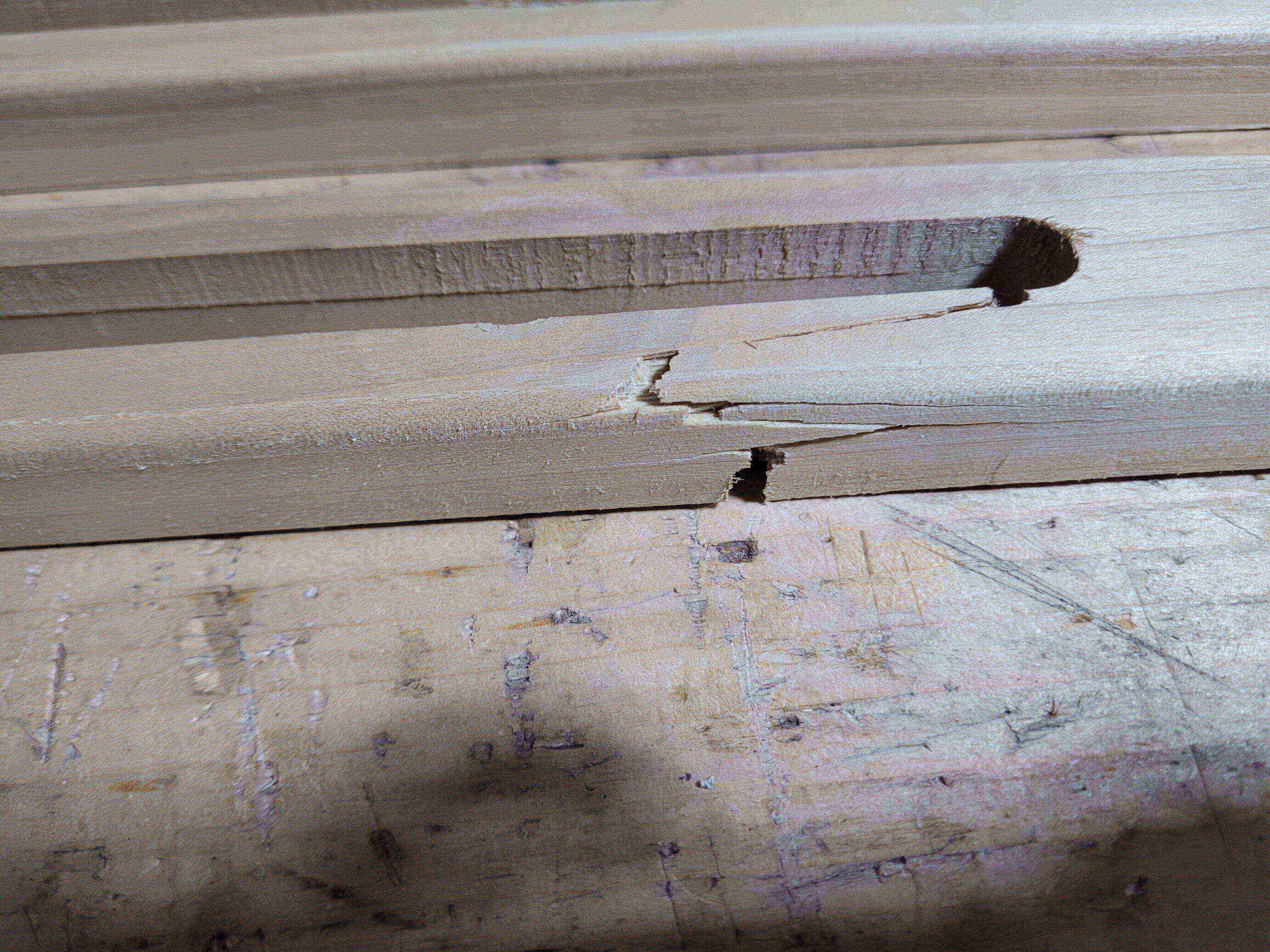

The failure. I’m going to make the new one a little wider, and close the slot at the bottom. Hopefully that will help it survive longer.

The only thing I had to hand is this 2 * 4. I’m going to have to resaw.

First I’ll give myself something of a reference surface. I clean up a face and an edge. I don’t even bother with the entire face. I clean just enough for me to make my batten out of. No checking for flat or straight. If it looks good enough, it is good enough.

Show the good batten to the stock and mark length and width, with a little extra width added.

Then I spot this knot on one end of the board, and add a bit more length so I can just cross cut it off.

Out comes my favourite rip saw, and the longest hardest part of the job starts.

An accidental but useful feature of my bench. When I am resawing long stock, it can slip in the vice as I work. But slipping the end under this holdfast in the bench leg makes it a little more stable and less likely to slip.

Resawing done.

Then another rip cut to take it to width.

Its quick on pine to get rid of the saw marks with a jack plane.

Then a quick pass with the smoothing plane. There are some spots that are still a little rough. No matter. This will be hidden when in use, and its not getting any finish.

Time to start laying out the holes and slots. No need to check for square or anything else. Eyeballing it when planing off the saw marks got me close enough. Place the existing batten on the stock and centre it. Use an awl to go through the existing bolt holes to mark the positions. Do the same at either end of the slot.

The transferred bolt hole marks.

The beginning of the slot

The end of the slot

I drop augers into the slot until I find one that is a snug fit.

The same with the bolt holes. 1/4 inch seems good here.

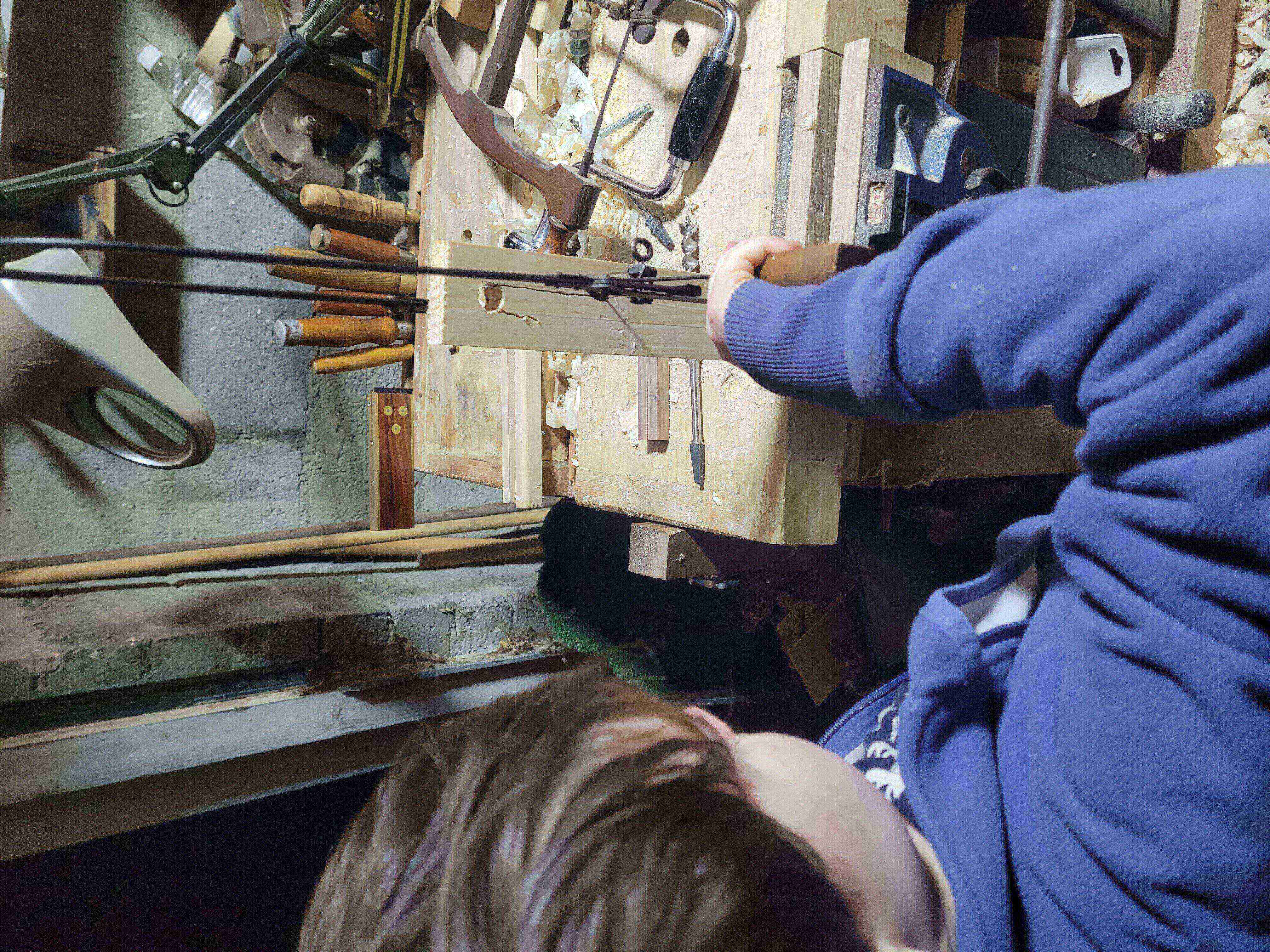

Time to get the apprentices involved. The oldest and youngest take turns drilling the holes with a brace.

Youngest needs some height assistance.

We only drill the start and end of the slot.

My tiny minions enjoyed countersinking the bolt holes.

Join up the slot start and end with a pencil

Then the littlest minion makes a start on the slot with a coping saw

We went as deep as we could, then finished with a hand saw. A little rough.

But he enjoyed smoothing it out with a rasp

And we have the replacement piece. This is where we finish. I know you have been anticipating a beauty shot of me posed on the bed showing a little ankle, but I’m going to let you down. It has been installed, works perfectly, and has survived several trampolining sessions.