Loom Shuttle

I’m beginning to close in on the finish line with the loom. The frame and heddle bar are just sitting around letting the purple come back in full after finishing. That leaves the shuttles and the comb to make. I’ve planed down some stock to about an 1/8th of an inch. The shuttle is going to come first. 2 shuttles in fact. If you are going to work the full width of the frame, then you want a shuttle about as wide as the frame. But for smaller, narrower pieces, a little shuttle will be quicker and less awkward to use. See the photos below for the process.

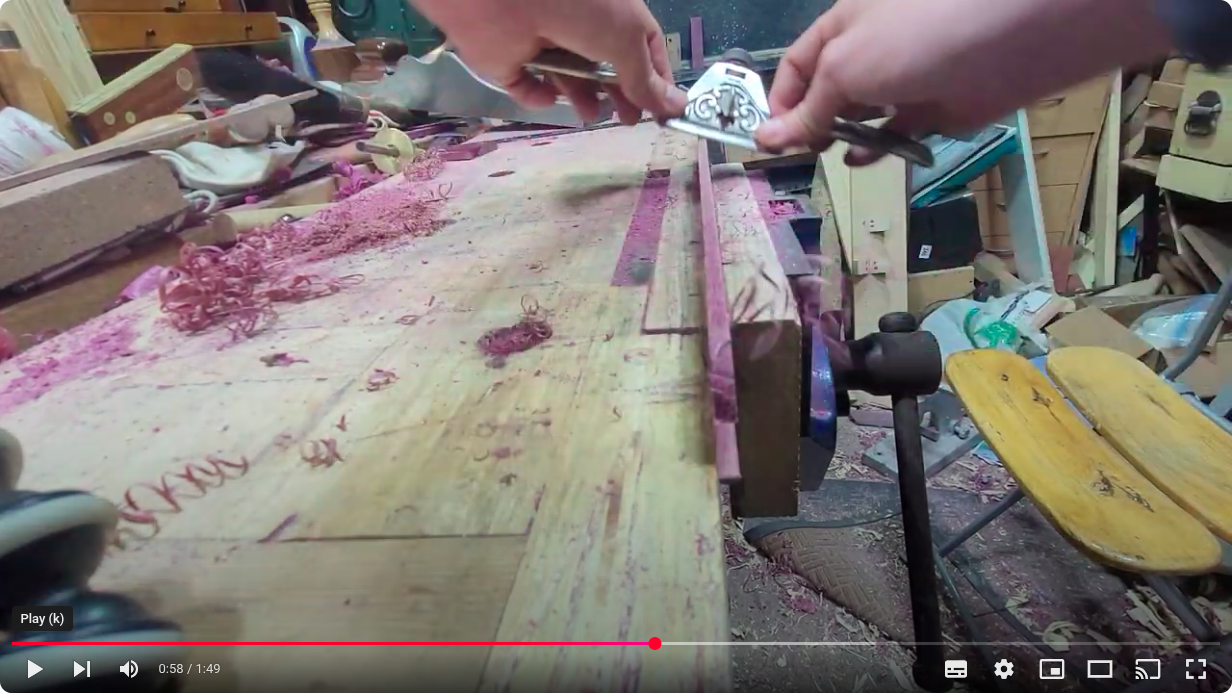

The marked out stock. I’ve also started the two vertical saw cuts. The end is going to be rounded off, this will make it tricky to start the saw afterwards, so I’ve made two small kerfs that go just inside the curve. If I cut them completely before rounding the end, it would make an already thin piece of stock much weaker, and I would be worried about accidentally snapping it while working. This way the piece gets lots of support while being rounded, while still making it easy to continue the saw cut while I’m done.

Its a bit tricky to see the layout pencil. So what you have here is an arc at the top, that describes the curved end. Then two vertical lines running down to the horizontal line, that will become a slot later.

I cant get a spokeshave to turn accurately enough to really match the curve I want straight away. I start off with a fine rasp, and create a slope that will make it easier to refine with the shave.

Then start working down to the line with the spokeshave. The shave goes a little quicker, and leaves a nicer surface. If I think I’m having a hard time getting the curve tight enough, I’ll refine a little with the rasp, and then switch back.

Left hand side is within a hair of the layout line, right hand side still needs a fair bit of work. I don’t care about the part between the saw kerfs, as that is going to be removed anyway.

And there we have it. Again, we don’t care about the area between the saw kerfs.

The spokeshaves leaves a pretty nice surface on the end grain.

And that’s both ends of the small shuttle rounded.

Now its time to drill out the hole at each end. The hole is where the yarn will rest as its wound around the shuttle. It also helps prevent the thin stock from splitting. In a thin piece like this, you are always drilling pretty close to the sides. A standard auger will likely split the work. It is time to use a centre bit. The tip of a centre bit works like a birdcage awl. It cuts fibres rather than forcing them apart like a snail. On a thin piece like this, use a backing board. Its quite possible you will simply snap your way through the end of the cut rather than cut your way through if its not supported from underneath. First drill into one face just enough to clearly mark the hole. Given how thin this is the point on the bit will be all the way through before that is done.

Then flip it over and drill through. Really remember the backing piece for this. The wing on the drill bit will probably cut all the way through before you remove all the wood.

Leaving you with a cut little button.

The finish your saw cuts till they meet the new hole.

As the shuttle is going to be passed through the yarn above and below it, we want it to slide and not catch. To help that, I’m going to round over every edge. This is quick and easy with a finely set spokeshave. Start off with a pass holding the shave at as steep an angle as you can. Then over 3 or 4 strokes work your way to just short of horizontal. Repeat until you can see you are hitting the centre of the piece. Then repeat on the other side, and you should have a pretty nice rounded edge. If its a little rough in places, a quick lick of sandpaper will even it all out. See the video for a demonstration.

I had a divil of a time getting my phone’s camera to focus on the curve, so apologies for the blurriness, but I think you can make it out well here.

I’ll use the spokeshave to round the curved ends as well.

And the inside surfaces get worked with a fine rasp to chamfer them a little. They done need to be rounded as much as the outside surfaces. A little chamfering will prevent yarn from catching on them.

Then its just scrape any tear-out I find. Sand it all evenly and we have 2 shuttles. I’ll leave them sit for a while for the purple colour to return and get even. Next up will be the comb.